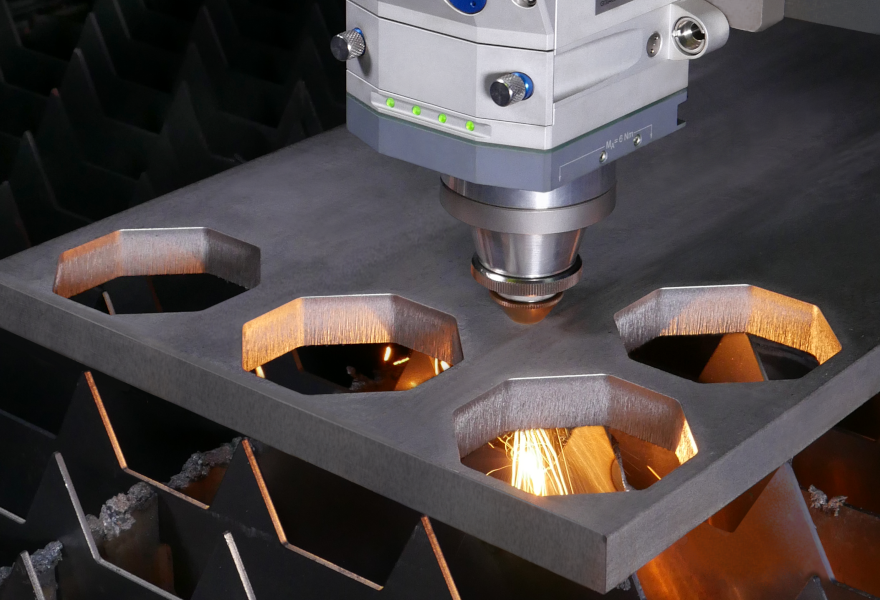

With a laser source power that reaches 12kW, the efficiency and control capacity of the cutting process of LS5, the BLM GROUP sheet metal laser cutting system, is derived from the synergy between the technical characteristics of the laser cutting head fitted on the machine and the specific technological solutions of BLM GROUP which are designed to optimize the entire sheet metal laser cutting process.

The most powerful version of the LS5 is equipped with a PRECITEC ProCutter Zoom 2.0 laser cutting head. Globally recognized for its superior quality, this component offers significant technical advantages for optimum laser cutting quality on sheets of all thicknesses and materials.

Advantages and technical features:

- The most advanced Zoom Optic technology is specific to the 12 kW laser power, with a vertical focus range from -30 mm to +15 mm, and the widest magnification range covering seven different zoom levels: 1.2, 1.5, 2.0, 2.5, 3.0, 3.5 and 4.0;

- Improved service gas flow fluid dynamics;

- 10 mm diameter optical fibre input connector;

- Maximized vortex-free flow with minimal pressure drop;

- Head optimized for both Nitrogen and Oxygen cutting;

- Focal position adjustment that is fully motorized by the CNC of the machine;

- X/Y centering without adjustment after nozzle changeover.

- Drawer with window to protect the internal optics from dirt and fumes, easy to change with no need for special equipment;

- LED indicator for monitoring pressure, temperature and contamination level.

PRECITEC ProCutter Zoom 2.0 laser cutting head specifically for 12 kW of power.

PRECITEC ProCutter Zoom 2.0 laser cutting head specifically for 12 kW of power.

Optimum cutting quality on all thicknesses and materials

The LS5 cutting head has a wide range of laser beam magnifications from 1.2 to 4.0 in (seven steps: 1.2, 1.5, 2.0, 2.5, 3.0, 3.5 and 4.0) for generating the most suitable radius for sheets of any material and thickness. On the LS5 the magnification is exploited to the fullest automatically by Active Zoom, the BLM GROUP feature that optimizes the size of the laser beam according to the cutting conditions.

High laser cutting power means faster cutting and the ability to process thicker sheets with better quality..

High laser cutting power means faster cutting and the ability to process thicker sheets with better quality..

In parallel with the automatic management of the Active Zoom beam diameter, which is particularly advantageous in high-power laser cutting, the LS5 also features Active Focus, a function for automatically adjusting the focus position in laser cutting according to the type of material and thickness.

High laser cutting power means faster cutting and the ability to process thicker sheets with better quality. In addition to the “power logic”, BLM GROUP adds Active Piercing, a function that both optimizes the piercing of the material by the laser beam and detects the end of it, to speed up the attachment step and avoid loss of the cut that causes waste in terms of both working time and material.

Active Piercing has:

- 12 perforation modes that the machine selects automatically according to the material and thickness to be processed;

- Laser cutting process control system with nitrogen. An additional Active Piercing function that many similar systems are lacking.

Active Piercing works by using a special sensor inside the laser source that uses a light detection technology exclusive to the BLM GROUP depending on the machine type and the installed power.

By exploiting the Active Zoom and Active Focus features that act intelligently on the mechanics of the optics inside the laser cutting head, the operator does not need to intervene in the adjustment of the parameters and only needs to define the material to be cut.

The machine will do all the rest. In addition to this, the PRECITEC ProCutter Zoom 2.0 laser cutting head has been developed by Precitec to optimize the flow of gas out of the nozzle.

High-gauge cutting quality can be further enhanced with the Active Cool feature that releases a water jet to cool the material as it approaches the cut.

Discover all the Active Tools functionalities for sheet metal laser cutting

Productivity resulting from full process automation

The LS5 12 kW offers extremely high cutting performance on any material or thickness. This is because, in addition to the power of the laser source, which has a direct impact on the productivity of the machine, the LS5 offers a significant reduction in overall cycle time by automating both the cutting and the sheet metal handling cycles.

On the LS5, all the activities, that in less advanced laser cutting systems are responsibility of the operator, are carried out automatically by the machine itself, such as:

- Sheet nesting that can be carried out offline on programming software and managed rapidly to the machine with the Active Camera;

- Automatic cutting parameter set-up, using the material and thickness database already in the machine created from BLM GROUP's decades of experience;

- Automatic nozzle changeover and wear monitoring: the machine with the Active Nozzle Changing function automatically changes the nozzle based on the material and thickness that has to be cut and monitors its wear;

- Automatic cutting process optimization offered by the Active Tools functionality.

Furthermore, in 24/7 processing, LS5 offers many possibilities using sheet metal handling and storage systems that can be integrated both at the purchase of the machine or later according to the production requirements.

LS5 on display at Blechexpo, equipped with an in-line pallet changer and tower warehouse..

LS5 on display at Blechexpo, equipped with an in-line pallet changer and tower warehouse..

Robust cutting process

Maintaining optimum cutting conditions throughout the process is essential. To keep the laser cutting conditions under control at all times, the LS5 head is equipped with advanced sensors to monitor component temperature, gas pressure and the level of contamination of the optical path. The status of the device can be constantly monitored by the operator via the LED indicators on the head, which allow the working conditions to be kept under control at all times.

In addition to this, the head is equipped with a window that protects the optics from smoke and sparks produced during cutting, the slide is sensor-controlled and the state of cleanliness and therefore the temperature of the slide is constantly monitored.

The cutting head is equipped with a window that protects the optics from smoke and sparks produced during cutting.

The cutting head is equipped with a window that protects the optics from smoke and sparks produced during cutting.

Reliability and reduced maintenance

The quality of the components and the technological solutions of the BLM GROUP, in synergy with the technology of the ProCutter Zoom 2.0 head, means that customers who choose LS5 have a system that is reliable in all conditions, simple to use every day and easy to maintain.

A further example of this synergy is the Active Nozzle Centering feature that guides the operator through the use of the laser beam centering adjustment system of the head.

To support everyday production, the LS5 also has a Help button that the event of unexpected issues, allows the operator to open a support ticket with the designated service center with a simple click. Using the Help button, the machine automatically sends the necessary information to the technical assistance service team to quickly solve the problem.

LS5 can also be equipped with the Active Mail function to keep updates everyone involved in production in real-time via email.

Simply provide the personnel email addresses and Active Mail sends them automatic notifications on the production status, scheduled maintenance and alerts relating to any unexpected issues.

Conclusions

Resulting from more than 35 years of experience in sheet metal laser cutting, LS5 is a top-of-the-range, fully automatic sheet metal laser cutting system that can be expanded, even after purchasing, both with automatic sheet handling and storage solutions and with the 100% automatic Lasertube module, with which it is possible to laser cut tubes and sheets metal with the same machine.

LS5 sheet metal laser cutting system, in a configuration with an automatic in-line pallet changer..

LS5 sheet metal laser cutting system, in a configuration with an automatic in-line pallet changer..

Using the ProCutter Zoom 2.0 laser cutting head, the LS5 can guarantee top-level cutting performance and fully exploit the power of the laser source of up to 12 kW.