Dimensiones, diseño, requisitos geométricos y mucho más; Al doblar el tubo, poder conseguir un radio de curvatura mínimo puede representar una ventaja considerable. Estamos hablando de curvaturas extremas caracterizadas por una relación entre el radio de curvatura y el diámetro del tubo inferior a 1 y que requieren un importante conocimiento tecnológico para alcanzarlas.

En este artículo veremos:

- cuáles son los parámetros tecnológicos que hacen difícil doblar un tubo;

- qué características debe tener una dobladora de tubos para minimizar el radio de curvatura;

- cómo calcular el grado de dificultad de una curva;

- una lista de tubos curvados con radio mínimo de curvatura y su campo de aplicación

Cuáles son los parámetros tecnológicos que hacen difícil doblar un tubo

Existen múltiples parámetros tecnológicos que influyen en la viabilidad del curvado de tubos de acero, aluminio, cobre u otros metales.

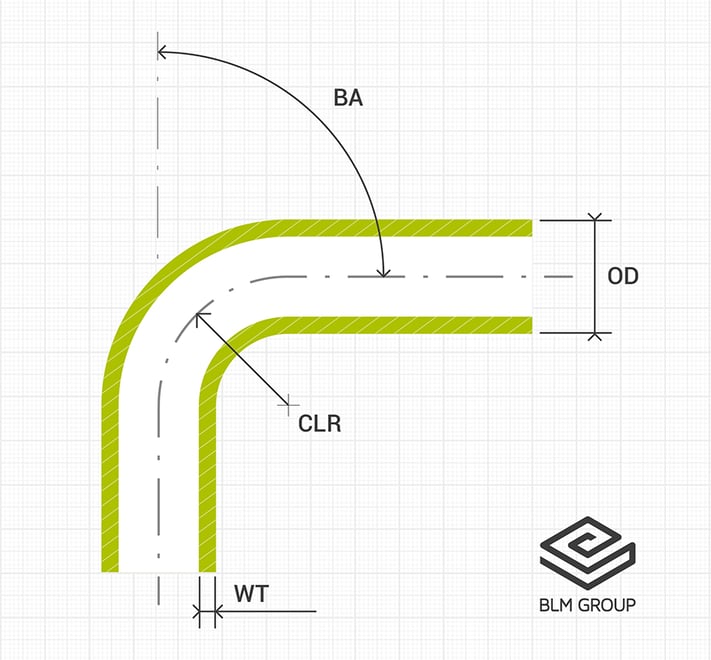

En primer lugar, hay que considerar los aspectos puramente geométricos que caracterizan la curvatura del tubo y son: el diámetro y espesor del tubo, el radio medio de curvatura y el ángulo de curvatura.

La magnitud de estos factores define un primer grado de dificultad para crear la curva de la que hablaremos en el siguiente punto.

La figura muestra los principales parámetros geométricos en el doblado de tubos: OD – diámetro exterior del tubo; WT – espesor de la pared; CLR – radio medio de curvatura y BA – ángulo de curvatura.

La figura muestra los principales parámetros geométricos en el doblado de tubos: OD – diámetro exterior del tubo; WT – espesor de la pared; CLR – radio medio de curvatura y BA – ángulo de curvatura.

La viabilidad de un tubo curvado obviamente no puede limitarse a calcular el grado de dificultad del curvado, sino que debe considerar también otros aspectos como: ángulo de curvatura, complejidad geométrica de la pieza, dimensiones de los componentes del equipo y del cabezal, dirección de curvado de la dobladora de tubos (que puede ser derecha o izquierda o derecha e izquierda en proceso), y los eventuales equipos especiales o ciclos de máquina particulares.

Más allá del ámbito puramente geométrico y especialmente cuando se habla de curvatura de tubos con un alto grado de dificultad, también es necesario considerar el material del tubo, el tipo de lubricación, las características de la dobladora de tubos como el par de flexión y la fuerza de empuje.

Más allá del ámbito puramente geométrico y especialmente cuando se habla de curvatura de tubos con un alto grado de dificultad, también es necesario considerar el material del tubo, el tipo de lubricación, las características de la dobladora de tubos como el par de flexión y la fuerza de empuje.

¿Qué características debe tener una dobladora de tubos para minimizar el radio de curvatura?

Las dobladoras de tubos capaces de obtener radios de curvatura de tubos muy estrechos son máquinas capaces de garantizar un perfecto control de la deformación del material del tubo. Esto sólo es posible mediante un control constante del movimiento de los componentes del equipo de doblado y las fuerzas que genera sobre el tubo.

Las dobladoras de tubos totalmente eléctricas de BLM GROUP permiten controlar mejor estos parámetros y en particular, para realizar un curvado con un alto grado de dificultad, pueden gestionar durante el ciclo de curvado:

- posición del mandril;

- par de sujeción;

- empuje de avance del tubo;

- empuje y movimiento de la matriz.

La hábil alquimia de estos y otros parámetros permite gestionar curvaturas de niveles extremos incluso sin experiencia especial en la curvatura de tubos.

Además, en el caso de que se produzcan arrugas o imperfecciones en el tubo curvo, a través de VGPNext el operador puede saber en qué parámetro intervenir para solucionar el defecto.

Cómo calcular el grado de dificultad de una curva

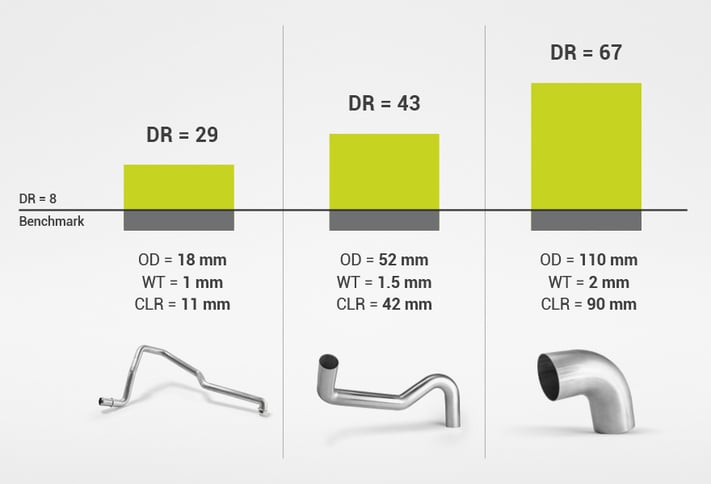

El grado de dificultad para doblar el tubo es el indicador que estima en términos puramente geométricos la dificultad de realizar una curva y se define como la relación entre el diámetro del tubo al cuadrado y el producto entre el espesor y el radio de curvatura.

OD es el diámetro del tubo

WT es el espesor del tubo

CLR es el radio medio de curvatura

Para tener un valor numérico de referencia del grado de dificultad de una curva, se puede afirmar que un DR = 8 está relacionado con una curva normalmente difícil que, para garantizar la ausencia de rayas, arrugas o cualquier pequeña imperfección, requiere el uso del mandril y una matriz.

A lo largo de sus más de 60 años de experiencia en el procesamiento de tubos, BLM GROUP ha desarrollado el know-how necesario para realizar curvas con radios de curvatura mínimos que se utilizan en diversos sectores industriales.

En la siguiente sección se enumerarán en detalle algunas de las aplicaciones más interesantes con su grado relativo de dificultad.

Hai un pezzo e vuoi sapere se è fattibile? Scoprilo subito!

Lista de tubos curvados con radio mínimo de curvatura y su campo de aplicación

Lista de tubos curvados con radio mínimo de curvatura y su campo de aplicación.

Lista de tubos curvados con radio mínimo de curvatura y su campo de aplicación.

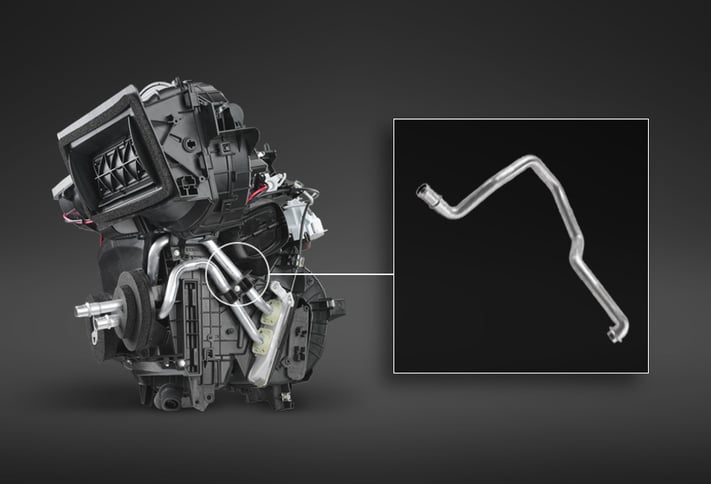

1. Componente para el sistema de aire acondicionado del coche

DR = 29

En el limitado espacio disponible en el interior del compartimento motor, el uso de componentes tubulares con radios de curvatura mínimos permite respetar las restricciones dimensionales y una adaptación precisa al diseño indicado por el proyectista.

DR = 29 - tubo con un diámetro de 18 mm y un espesor de 1 mm , con un radio de curvatura de 11 mm.

DR = 29 - tubo con un diámetro de 18 mm y un espesor de 1 mm , con un radio de curvatura de 11 mm.

2. Componente de escape

DR = 43

Para mantener la aerodinámica del vehículo, los componentes del escape deben poder caber dentro de los espacios restringidos permitidos por el chasis.

DR = 43 - tubo con un diámetro de 52 mm y un espesor de 1,5 mm, doblado con un radio de curvatura de 42 mm.

DR = 43 - tubo con un diámetro de 52 mm y un espesor de 1,5 mm, doblado con un radio de curvatura de 42 mm.

3. Pedestal para taburete de diseño

DR = 67

Las curvas con radio de curvatura extremadamente pequeño permiten definir formas innovadoras, con un diseño atractivo y estéticamente impecable al no tener uniones soldadas.

DR = 67 - tubo con un diámetro de 110 mm y un espesor de 2 mm, curvado con un radio de 97 mm.

DR = 67 - tubo con un diámetro de 110 mm y un espesor de 2 mm, curvado con un radio de 97 mm.