Are you considering introducing a new machine in your factory to optimize your metal cutting processes? If the answer is yes, then you’ve certainly considered a number of different technologies in order to understand each of the pros and cons in relation to the specific needs of your production.

There are many solutions for metal cutting and if you want a complete overview, you can read the article entitled "3D metal cutting: how to choose the right technology for your production plant".

In this article, we will focus on 3D laser cutting, which is unquestionably one of the most modern and technologically advanced solutions.

|

|

| Example of a 3D laser cutting system |

But is it always the best choice?

That depends. You have to understand whether it is worth your while because a system like this is a big investment and you must properly consider whether it will bring significant medium- and long-term benefits.

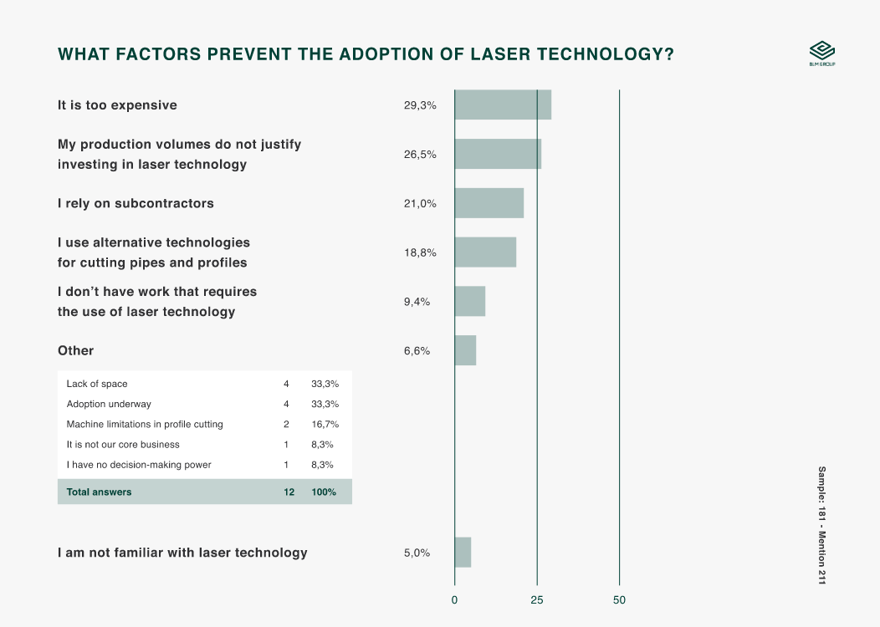

The following table shows some results of the Go-To-Market analysis: Increasing effectiveness in value proposition, conducted from April to May 2017 on a total sample of 397 units (BLM Group laser customers / competitor brand laser customers / non-laser users). As you can easily see, the factors holding back laser adoption are many and should not be underestimated.

We will then look at a number of cases in which investing in 3D Laser Cutting can make a real difference:

- When a laser system can replace a number of machining operations, therefore reducing the time and cost per part

- When first and foremost flexible technology is required

- When cutting quality is very important.

- Specific industries and processes for which 3D laser cutting is particularly suitable: Automotive, Aerospace, Furniture and Design.

How can laser technology drastically reduce the cost per part

When it replaces multiple machining operations. It is estimated that using laser technology to cut metals can generate a reduction in the cost per part of from 50 to 90%.

That is a major saving, mainly due to the benefits of this technology:

- The possibility of making complicated geometries with negligible increases of cost

- High productivity and flexibility

- Creation of joints which allow connections with other components to simplify welding

- Fabrication of prototypes and preproduction parts at the cost of large volume production

- Less personnel: laser processing requires on average five people less than traditional technologies

- Smaller machinery: from 20% to 30% less space compared to traditional processes

- Machining accuracy close to one hundredth of a millimeter, which reduces waste and subsequent finishing operations

Flexibility: the three elements to consider

Laser technology is characterized by flexibility because it doesn’t require any tool changes and lends itself to cutting different materials. To obtain concrete advantages, it is necessary to choose high-end machines, equipped with simple and versatile programming software

Here are some features to look for in a flexible 5-axis laser cutting system:

- Programming software

To quickly program a new operation, the software must be able to:

-

- Program a new production batch off-line, while the machine is processing a different job, in order to go straight in to production

- Import 3D files from third-party CAD software

- Quickly identify cutting paths

- Identify and solve potential potential critical points and improve the work cycle easily and intuitively

- Simulate your work cycle and start production in complete safety.

|

|

| Example of programming software for a 3D laser cutting system |

- Automatic cutting parameter optimization

A flexible laser cutting system automatically optimizes cutting parameters based on a number of factors, including cutting speed, thickness, type of material to be cut, and head inclination. - Fixtures and material handling systems: These make it possible to avoid both the use of expensive fixtures and expensive loading and unloading operations.

Quality, freedom, and speed of cutting is where the laser makes the difference

A 5-axis laser cutting system consists of a laser cutting head mounted on an interpolated 5-axis CNC system.

The 5-axis solution, which is commonly used in milling and turning systems, becomes a technology that sets new standards for productivity and flexibility when integrated with the laser.

- Cutting speed

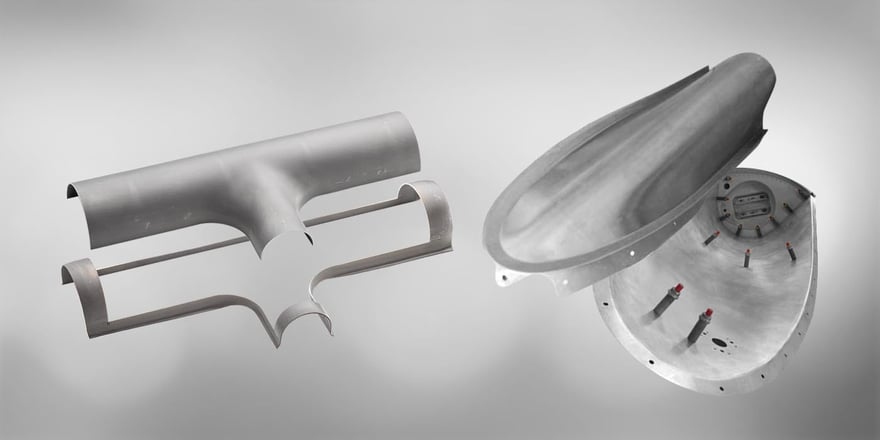

The laser allows extremely fast and accurate cutting without deformation or breakage. - Freedom of head movement

The 5-axis motion of the head allows complex geometries to be cut on three-dimensional profiles, such as curved tubes, hydroformed tubes, stamped sheets, and drawn tubes. The motion systemallows the cutting head to be tilted to reach even positions on the surface that are particularly narrow or impossible for a milling machine. - Variety of materials

The fiber laser allows you to cut a wide variety of materials, including stainless steel, steel, copper, brass, aluminum, and titanium alloys. Unlike traditional cutting methods, there is no need to change tools based on the material to be cut: the laser beam is the only "tool" required. Find out more about - Integrating several operations into one

Drilling, milling, deburring: thanks to laser cutting, a wide variety of chip removal operations can be replaced in one fast, fast and repeatable operation. Find out more about - Thin material

The laser is even more advantageous on extremely thin materials which are difficult to process with chip removal systems or other types, such as plasma and oxyfuel cutting. With laser cutting, all thermal effects near the cutting path are eliminated, as well as the mechanical deformations typical of mechanical cutting methods, such as blanking and punching. - Automatic cutting parameter optimization

As a result of continual investments in R&D, there are systems on the market that can automatically and optimally manage focus position, adjust gas pressure and many other parameters to ensure maximum cutting quality and ease of use at all times.

Laser, a solution of excellence in many industries

Some industries, more than others, are shifting rapidly towards this technology.

Automotive

3D laser cutting is an excellent solution for the production of a wide variety of parts:

- Hydroformed (arms, suspensions, mechanical supports)

- Stamped sheets (internal parts of the bodywork, luggage racks, doors)

- Curved tubes (exhaust system, chassis, support bars)

In this area, laser systems allow you to:

- Cut a wide variety of even extremely thin and lightweight parts very fast, without altering the shape or surface conditions

- Make highly precise cuts while maintaining the quality of the cutting profiles

- Cut even very complex three-dimensional shapes

Aerospace

This sector has always been characterized by the highest quality standards in terms of precision and quality, as well as the use of light and resistant materials, such as titanium or aluminum alloys.

When making parts with a special geometry, advantages deriving from the use of laser include:

- Non-contact process,unlike cutting or chip removal processes, which prevents deformation or micro-fractures.

- Precise and fast cuts with no heat-affected zone.

- Elimination of the cutting fluids and chips typical of machine tools.

- Possibility of combining multiple operations into one, reducing the handling of semi-finished products.

- Ability to cut titanium and aluminum alloys.

Furniture and design

Laser reduces energy consumption and the number of processes necessary to obtain parts with even very complex 3D geometries and excellent finish, giving the opportunity for designers to achieve the shape they envisioned without trade-offs.

Using laser is like working with an extremely fine tip pen. This leaves brilliant designers free to express all their creativity.