Innovation, essential to excel in metal cutting. To say that innovation is important today is almost an understatement, given that technological progress is affecting every industrial sector.

The main factors on which innovation itself can bring real benefits include:

Efficiency

- The need:

- Manufacturers in developed countries need to focus on efficiency to maintain their leadership, because emerging economies are striving to win market shares by exploiting the lower cost of labor

- Manufacturers in developed countries need to focus on efficiency to maintain their leadership, because emerging economies are striving to win market shares by exploiting the lower cost of labor

- The technological answer:

- 3D laser systems

- Handling robots

- Automatic cutting parameters set-up

Find out how to combine these technologies in a single machine

Energy saving

- The need:

- To protect the environment

- To respond to increasingly tougher policies and laws

- To introduce more energy-efficient solutions

- The technological answer:

- Fiber laser is three times more energy-efficient than its CO2 counterparts

Feasibility

- The need:

- To be able to make products which were previously impossible to produce or to create existing products but with improved and more efficient methods and processes

- To be able to make products which were previously impossible to produce or to create existing products but with improved and more efficient methods and processes

- The technological answer:

- To combine several processes in a single work cycle

- To avoid manual repositioning of the workpiece by the operator

- Utilizing the robot to manipulate the part to cut features on opposite sides of the part

An open-minded investment

A forward-thinking company must take into account the main market trends and the needs of its customers:

- Increasing use of 3D profiles

In order to save on material and component weight, the use of irregular-shaped parts such as deep-drawn, hydroformed or tube components has become more commonplace in the mechanical field as a result of FEM analysis and advanced 3D-CAD systems. - The need to combine multiple operations

For very thick workpieces, several independent machining operations, such as cutting or drilling, are required. A machine capable of combining multiple operations in a single work cycle provides competitive advantages in terms of efficiency and productivity. - The need to reduce processing waste

No scrap, tools or cutting fluid. A cleaner process means saving costs for the company. - The goal of being competitive on small production batches

High-mix, low volume production becomes practical with a high-tech machine solution. Programming and set-up from one job to the next is easily accomplished. - Making high-tech systems accessible to all

Investing in smart machine tool technology reduces the time required to train your operators, no matter what skill level, making it easier to attract and retain employees.

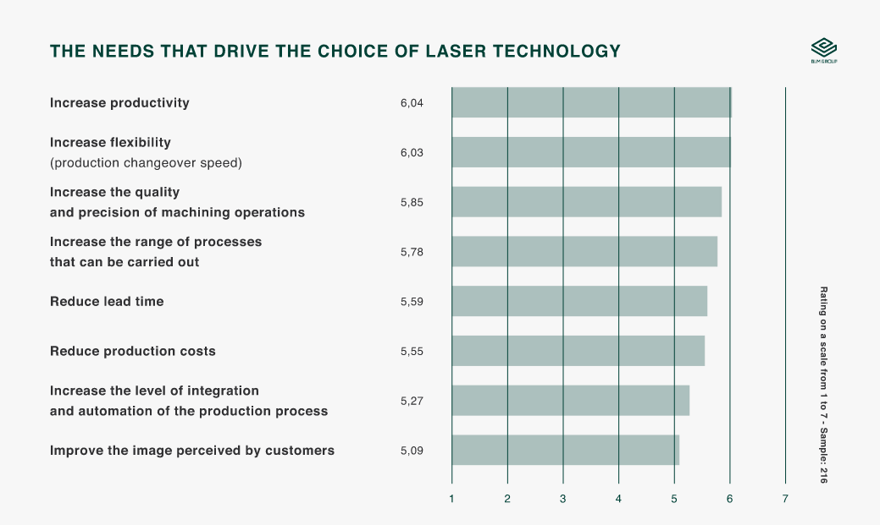

The following table shows the results of the Go-To-Market analysis: Increasing effectiveness in value proposition, conducted from April to May 2017 on a total sample of 397 units (BLM Group laser customers / competitor brand laser customers / non-laser users).

Can 3D laser cutting turn my company into an industry leader?

The answer is not a simple one. It depends on the type of company and machine chosen.

The case of subcontractors

- The context: The world of the job shop and contract manufacturer is constantly changing. Batch sizes and types of parts differ from project to project. Often, caught between the demand for quality and that of keeping the price of production low to compete with national or international rivals.

- The solution: To open up new markets and increase your efficiency.

- The 3D laser answer:

- Automotive, aerospace, motorcycle, HVAC are all markets in which the laser processing of complex three-dimensional profiles can create a real competitive advantage.

- Feasibility of the parts made.

- Productivity and speed of production, thanks to simple programming and part set-up.

|

|

|

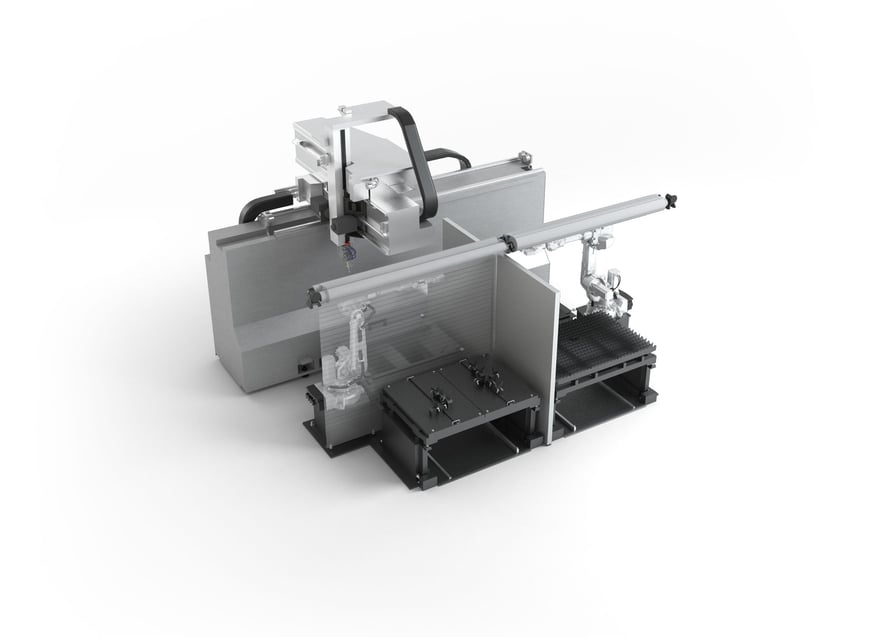

Example of a 3D metal laser cutting system |

Find out more about the applications of 5-axis laser systems

The case of the Original Brand Manufacturer

- The context: there is a need for renewal, keeping production costs low, in order to be able to sell at a competitive price offering the highest quality. One of the main challenges can be correctly identifying the products that the market needs.

- The 3D laser answer:

- The technology allows an almost unlimited variety of possible creations, from design to mechanical uses.

- It allows you to make prototypes, estimate production and run production in a simple and fast way.

Discover the Arrow case study

Find out how to program a 3D laser cutting machine

The main solutions for 3D laser cutting

There are several 3D laser cutting systems on the market with variations of features and functions. Beyond the different brands and models, someone who is about to make a purchase must evaluate which are the most suitable solutions, according to actual needs.

- Combining productivity and precision by part processing with robot

We’re not simply referring to robotic part load and unload, but part manipulation during the cutting process. The robot can move the part to several different cutting positions, so the cutting head can reach any position on a complex part and always have the maximum degree of freedom at its disposal.

By avoiding manual repositioning, this solution ensures greater accuracy, increases productivity and avoids operator errors. - Is it always convenient to have 3D laser cutting and welding all in one system?

Equipping your laser cutting system with a welding head allows you to combine two processes on the same machine. There are two main disadvantages to this solution:

- It is not easy to replace a cutting head with a welding head. You need to stop the machine, employ highly qualified personnel and ensure a clean working environment.

- The cost of a hybrid laser welding and cutting system is very high, in some cases even higher than that of the two dedicated systems.

- Within certain limits, having the two processes on the same system can be an advantage, but as production volumes increase, it may be more convenient to carry out the two operations in parallel.

- Generally, the configurations of laser cutting machines are different from those of welding cells, which can lead to less than optimal processing results.

- It is not easy to replace a cutting head with a welding head. You need to stop the machine, employ highly qualified personnel and ensure a clean working environment.

- Advantages of automatic restart

Unexpected events may occur during a cutting operation which interrupt the process and force the operator to reject the part, resulting in 2x the loss: cost of material and work performed by a previous operation (e.g. bending, hydroforming, molding, drawing). Automatic restart systems are capable of interrupting work and picking back up where the process stopped. This applies to all machine components – loading, unloading, cutting head, and robot.

Which 3D laser solution is best suited to my needs?

If your goal is productivity, you need to focus on automation.

The implemented solutions depend on many factors, including the degree of automation or the scope of application. The machine could be equipped with:

- Single sliding door: The operator has to wait for the machine to finish cutting, before replacing the part.

- PRO: This is more economical than other loading/unloading methods. Loading is easy and allows better access to all machine parts, including the cutting head

- CONTRO: Laser downtime

- PRO: This is more economical than other loading/unloading methods. Loading is easy and allows better access to all machine parts, including the cutting head

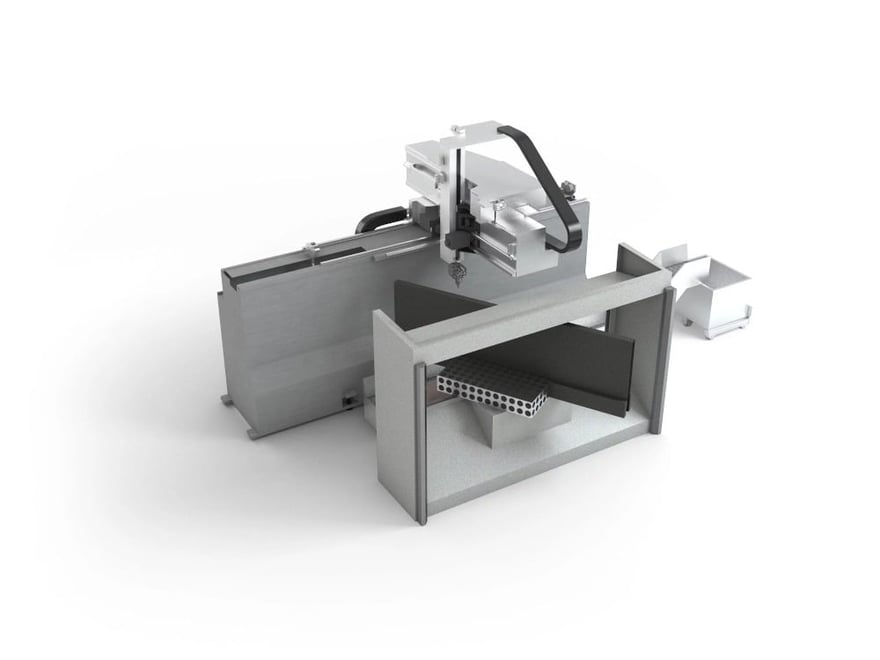

|

| Example of 5-axis laser system with sliding door |

- Dual shuttle table: Part loading and unloading is done in parallel while laser processing, so there is no impact to cycle time

Example of double mobile table - Rotary indexing table: This allows the machine to be loaded and unloaded while the machine is processing

Example of turning table

If you're looking for flexibility, then production set-up speed makes all the difference. Many factors play an important role in this:

- CAM software for programming the work cycle: It must be fast to import the part, simple to use, and powerful.

- Simple and intuitive user interface: The ability to interface it with other machines from the same manufacturer is a must, but more important is the possibility for allowing any operator to carry out the remaining set-up steps quickly, making any changes needed to the program and complete control of the system.