How much does a 3D laser system cost? Is price the only variable to consider? Or should you dive deeper?

First of all, what figures are we talking about?

The investment can vary substantially from case to case. We can identify different price ranges according to the maximum configurations of the system. Consider that prices should include installation and training:

- Single station models with single table: The price of a good quality system starts from half million Euro and can rise parallel to the size of the working area and the power of the laser.

- Version with dual working chambers with two tables or a rotary table: Here prices range starts from over half million to a million Euro or above. In these cases, the increase in productivity justifies the higher cost. This type of system is suited for high-volume manufacturing.

- Some machines offer the possibility of working more productively and with greater precision with curved and hydroformed tubes, for instance using the robots.

- The price increases even more when you introduce a spindle for cutting straight tubes or a welding head.

Find out more about 5-axis laser configurations

I have received several quotations. How can I compare them and choose the one that suits me the best?

When purchasing a 3D laser cutting system, price is not the only variable or even the most important. Here are the main factors to consider:

- The cost per part: A new machine must guarantee a lower cost per part and allow you to amortize the expenses of the system in the predetermined timeframe. Therefore, an efficient and productive system may be considerably cheaper than a less expensive, but also less efficient one.

- The cost of downtime: A system must minimize the time needed to switch from one production to the next. Sometimes it can be cheaper to have a more expensive system which allows you to switch production quickly.

- Service: What services can the system manufacturer offer? Is there a service center near you? It is important to ask yourself these questions because:

- Remote service, maintenance and training plans allow you to operate efficiently and safely as well as minimize unforeseen expenses.

- A local service center, with staff who speak your language, allows you to save on travel costs for technicians and facilitate communication, speeding up work.

Always evaluate the reputation of the manufacturer of your new system in terms of service!

- Total footprint: A large machine may require renting new space or may affect your internal logistics. Evaluate all the deriving costs carefully.

How can I calculate the cost per part?

You can calculate the cost per part by adding up various costs:

- Production cost: This is obtained by multiplying the "hourly rate" consumption of the machine by the production time. The hourly rate is the cost of the machine in terms of energy, gas consumption, maintenance costs, etc. for one hour of operation.

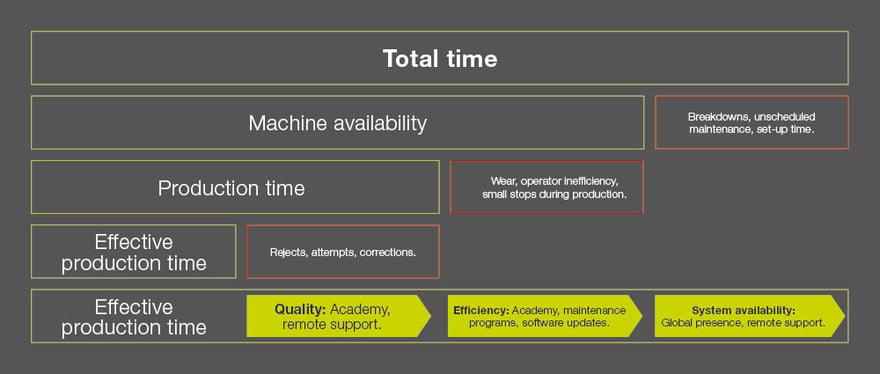

- Passive costs: These derive from the downtime of the machine. The estimated downtime determines an indicator known as "Overall Equipment Effectiveness".

Overall Equipment Effectiveness is a benchmark of the actual production in relation to the total available time and takes three important factors into account, system availability, efficiency or speed which the system operates and quality rate (“good” parts compared to the total number of parts made). Our advice is always to choose suppliers who have targeted service plans to maximize OEE.

|

| Model for calculating real-time productivity |

What are the real costs? What extra costs will I have to pay?

Of course, there may be extra costs when purchasing a 3D laser cutting system. Here are the main ones:

- Dedicated gas system: Always consider that the laser needs service gas, whether it be nitrogen, oxygen, argon, air. Therefore, you will need to install a dedicated system, which guarantees the right pressure, flow rate, etc. Important: if you decide to use compressed air, do not think the compressed air system in use in your plant will do. Higher pressures are required and the air must still be filtered before entering the optical circuit. For this purpose, it may be useful to have a system already prepared to accommodate various types of service gas.

- Power supply: Always evaluate the power you need and ensure you have the required power and amperage to supply the machine and ancillary equipment.

- Operator training: Your operators must be trained to use the system safely and efficiently. Choose a manufacturer that can offer you training sessions. Some manufacturers offer dedicated pre- and post-installation training plans included in the price and a wide range of training courses that you can use in the future.

- Personnel: You will have to think about whether you will need to hire new personnel after purchasing a new machine.

These are all factors that will allow you to calculate the ROI (return of investment) of the system you want to buy.

Find out if 3D laser cutting is the right solution for your jobs