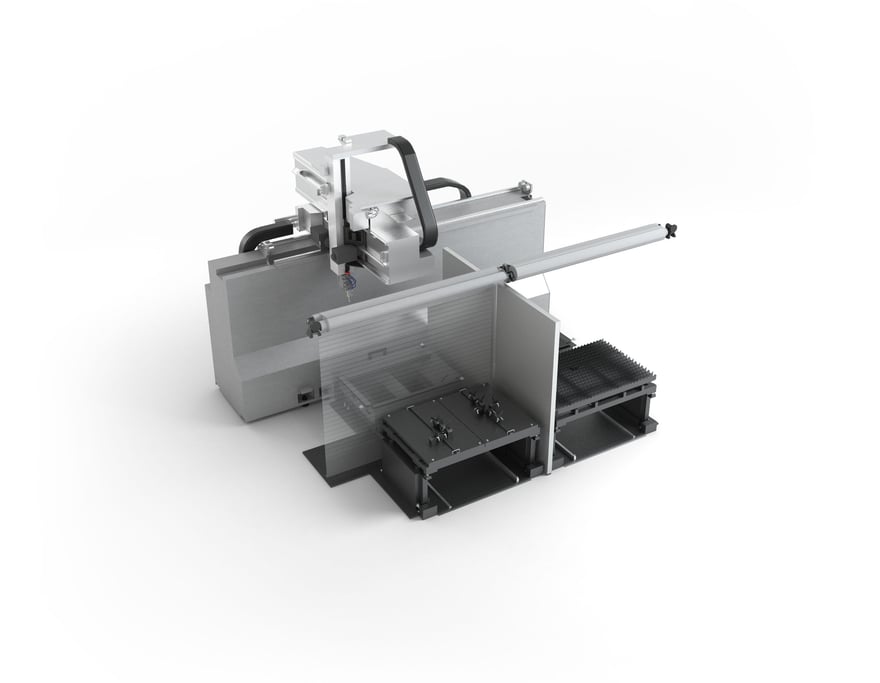

LT-FREE is a 5-axis fiber laser cutting system designed by BLM GROUP for processing any 3D part:

- Any three-dimensional profile, including curved, hydroformed, flat or stamped sheet metal, pre-welded and pre-formed tubes.

- A wide variety of materials, such as mild steel, stainless steel, aluminum, titanium, and copper alloys.

Compared to other technologies and similar machines in the market, LT‑FREE stands out for:

- The ability to quickly change production allowing you to program a new work cycle off-line and start production very fast.

- The many workpiece handling possibilities because the system can be equipped with handling robots or with shuttle or rotary tables to process the most varied profiles.

- The wide variety of possible configurations to suit the most varied sectors or applications.

- Active Tools because the machine can be equipped with a full range of automatic functions, capable of optimizing the laser cutting parameters in real time and making set-up operations extremely simple, guided and fast.

These aspects, which are the result of years of experience of BLM GROUP in laser cutting, firmly place LT-FREE among the high-end 5-axis laser cutting systems, able to offer real advantages in terms of flexibility, quality and productivity.

|

|

| LT-FREE - 5 axis laser cutting machine |

Let's now consider some fundamental aspects for someone who is buying a machine of this type:

- How long does it take to switch from one process to another?

- How the workpiece is handled?

- What are the possible configurations?

Learn more about the main differences compared to other 3D lasers

Switching from one machining operation to another in no time: the simplicity of LT-FREE programming

In terms of work cycle programming, LT-FREE allows you to switch from importing the 3D profile on CAM software to cutting on the machine in a simple, fast and guided way.

The workpiece is programmed using ArtCut, the specific CAM software for LT-FREE which allows you to:

- Import any 3D profiles, curved tubes, hydroformed tubes, drawn parts, flat or stamped sheets, etc...

- Program the new work cycle off-line in the office while the machine is engaged in production.

- Identify and simulate cutting paths automatically to avoid collisions.

- Program all work cell systems, including handling robots and shuttle tables.

|

|

| ArtCut: BLM GROUP CAM software for programming the laser cutting of any three-dimensional part |

Once the work cycle has been programmed and simulated, it can be sent to the machine.

The user-friendly machine interface allows even beginner operators to set-up production quickly and easily.

Among the additional features of ArtCut, here are the most interesting:

- Automatic generation and modification of support fixtures for drawn and stamped parts. The support templates can be created and modified quickly and intuitively by cutting out the various sheet metal parts with the LT-FREE itself. This is a very useful feature in the production of prototypes or small batches where, given the high number of production changes, it would not be convenient to commission the support templates from an external supplier.

- Scrap management on pre-bent tubes. Importing a pre-bent tube may not include the presence of scrap, which is generally a direct consequence of the tube bending process. With ArtCut, you can add scrap while programming the cut, either directly on the software or by importing it directly from VGP3D (BLM GROUP tube bending software).

- Adding micro-joints to the workpiece. The micro-joints allow the scrap to remain attached to the workpiece, preventing it from falling and damaging the internal parts of the machine or the part itself. The addition of micro-joints is not just a function of Artcut: it can also be done by the operator directly on the machine by using the unified interface.

Find out more about ArtCut and the unified interface of LT FREE

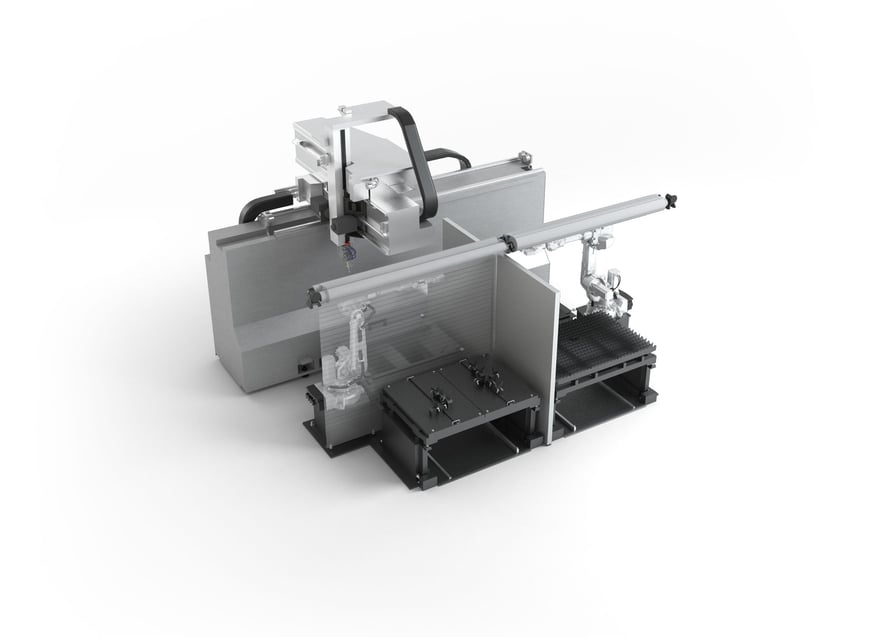

How is the workpiece handled? The many possibilities of LT-FREE

Workpiece handling is one of the features that characterizes the flexibility of LT FREE, offering manufacturers great value features and different configurations for their production needs.

- Handling with robots (present in HIGH FLEX and ONE FLEX configurations)

Particularly useful for curved or hydroformed tubes or where it is necessary to process a workpiece "suspended" in space, the purpose of the robot is to complete the cut in single automatic cycle by moving it to two or more positions. This avoids manual repositioning, which introduces errors between the geometries of the first cycle and those of subsequent cycles and has a negative impact on total productivity. For example, the bent tube can be processed along the entire circumference and/or on both ends with the aid of the robot. Once the cutting operations are freely defined by the operator, the robot gripper and workpiece act as one and no repositioning will be necessary. This means that the robot can ensure maximum precision in a single grip.

- Shuttle tables or single rotary table (present respectively in HIGH/MID FLEX and PIECE VALUE configurations). These solutions allow 24/7 production and enable work in the background.

- Support fixtures: The use of the robot does not overshadow the need to support the part, which continue to play a key role in profiles, such as drawn and stamped parts. On LT FREE, the combined use of support fixtures and robot allows the generation of "hybrid" work cycles, to perform all the necessary operations on a part in a single work cycle, drastically reducing the cycle time.

One configuration for all needs

The variety of handling systems available on LT FREE has made it possible to develop configurations that meet every possible need, while always guaranteeing the flexibility and productivity typical of this 5 axis laser cutting system.

- ENTRY LEVEL

Suitable for preformed, hydroformed, pre-assembled and flat sheets. It is provided with double fixed work table to mount dedicated tooling, ideal for machining even large pieces.

- ONE FLEX

The wide fixed work table combined with a handling robot. It is a hybrid version suited for machining flat and preformed sheets, hydroformed and pre-assembled, but also curved tubes and parts which require robot manipulation.

- PIECE VALUE

This version includes an integrated rotary indexing table, which provides for the presence of a rotary table, ideal for high-volume production of a wide variety of 3D parts: preformed sheets, hydroformed, pre-assembled and bent tubes.

- MID FLEX

Equipped with dual shuttle tables, it is suitable for machining preformed, hydroformed, pre-assembled and flat sheets. Processing alternates between the two worktables so production can run uninterrupted.

- HIGH FLEX

This version combines the dual shuttle tables with a dual robotic handling. It allows the processing of preformed, hydroformed, pre-assembled sheets, flat sheets and bent tubes for high throughput and flexibility.

Active Piercing, Active Focus, Active Speed, Active Gripper – the tools for total control of laser cutting

Talking about LT-FREE as a mere 5-axis laser cutting system is definitely not enough: for a technology of this type, it is essential to know how to recognize the quality and, above all, what advantages an advanced system can offer.

Together with the simplicity of programming and the rapid set-up of production, the Active functions are the cornerstones on which LT-FREE is based.

Active Piercing: detect material breakthrough and increase cutting quality

This feature optimizes the piercing function to stop as soon as breakthrough is reached and provide stable transition to the cutting path. This tool is specifically useful when processing parts and bent tubes with inconsistent material thickness (stamped or hydroformed parts often have this problem).

- The main advantage of Active Piercing is that it makes it easier to start workpiece production on the machine. It is often not possible to know in advance the precise thickness of the piece, which can vary in an unpredictable and inconsistent way. Active Piercing optimizes the piercing process automatically, whatever the thickness of the workpiece, eliminating waste because the piercing is right from the start.

- In the case of profiles with different thicknesses, being able to reduce the piercing time of the material in the thinner area and increase it where it is thicker saves time which is compounded by the number of attachments on the workpiece.

- In the case of bent tubes, Active Piercing immediately interrupts the operation once the material has been pierced, preventing heat input to the opposite side of the tube.

- Active Piercing also acts as a process control, preventing the laser cutting drift and subsequently recast.

Active Focus: Control of the focus position

The focal position is automatically adjusted to optimize cutting performance and quality based on material type, thickness, and angle of the cutting head on the part.

Active Speed: Control of all laser cutting parameters

This dynamically and automatically optimizes the laser cutting parameters according to their mutual interaction, in order to always obtain a perfect cut in the best conditions.

Active Speed controls and automatically all the main cutting parameters: power, frequency, duty cycle, focus position, assist gas pressure and speed.

A practical example is the tilt trimming and cutting of complex geometries, such as hydroformed, stamped parts etc., where the head is generally switches continuously from tilt cut to orthogonal cut and vice versa. Here Active Speed automatically adjusts all cutting parameters to always ensure the highest quality.

Active Gripper: Intelligent clamping system

Ensures automatic clamping of the workpiece. This allows the pneumatic clamps to open and close individually when the laser passes through.

The use of Active Tools allows LT-FREE to achieve levels of productivity, flexibility and robustness unprecedented in all levels of manufacturing -small, medium or large size batch.