As a high-end system, LT-FREE utilizies technology similar to that of the products of other major players in the sector.

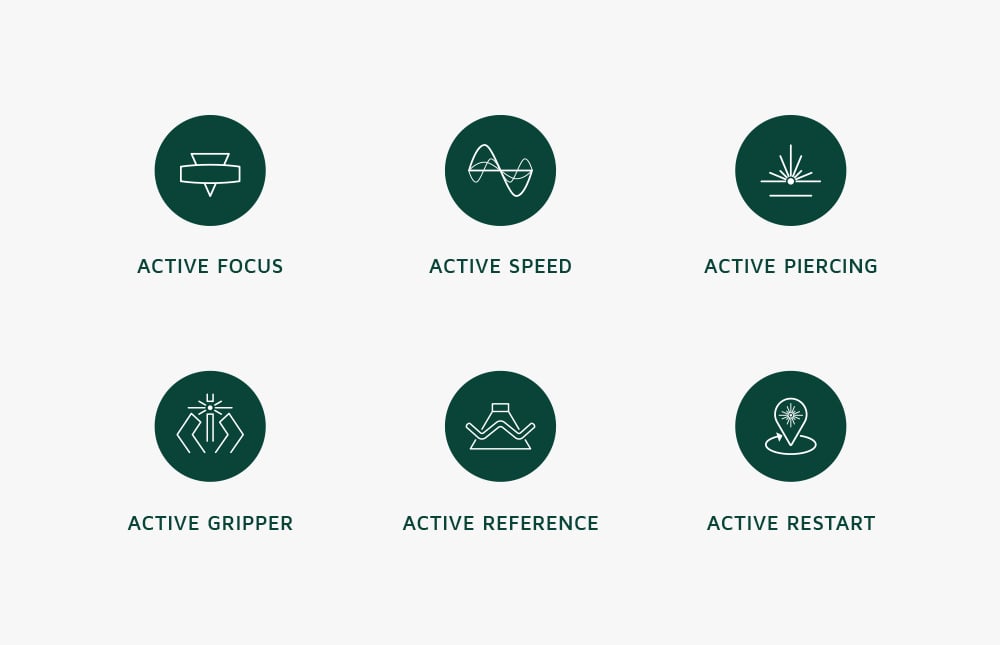

BLM GROUP has developed Active Tools to optimize the entire cutting process:

- Active Speed dynamically and automatically controls all the main cutting parameters: power, frequency, duty cycle, focus position, assist gas pressure and speed.

- Active Piercing improves productivity, automatically adjusting to variable material thickness on the same workpiece, identifying any abnormal operating conditions and avoiding generating bad parts.

- Active Focus is the system for controlling and varying the laser focus position according to 2D/3D cutting conditions and material.

- Active Gripper allows the automatic workpiece clamping. Each clamp opens and closes automatically to allow the passage of the laser. This eliminates the need to reposition and means deep-drawn or cold-forged parts, which during cutting are subject to change of shape due to stress resulting from the previous processing steps, can be held in position.

- Active Restart: if unexpected events interrupt the cutting process, LT-FREE can restart and complete the cutting process to avoid having to reject the workpiece.

The 5 main differences between LT-FREE and other 3D laser cutting systems

- Flexibility

The LT-FREE allows you to go from the 3D model to the finished piece quickly. - Tube management

In designing LT-FREE, BLM GROUP has benefited from over 60 years of experience in the production of tube processing machines.

The result is a three-dimensional laser system perfect for processing any type of tubular component (bent or hydroformed tube):

- The programming software manages scraps, i.e. the straight parts of the pipe, left downstream by the bending process.

- The robot can move the part to several different cutting positions, so that the head can reach any area on a complex geometry and always have the maximum degree of freedom.

- The programming software manages scraps, i.e. the straight parts of the pipe, left downstream by the bending process.

- Reducing human error

Robotic repositioning of the workpiece, offers greater precision, increasing productivity and prevents errors due to manual repositioning. - Simplicity

The innovative graphic interface is common to all other BLM GROUP laser systems and is designed to facilitate the use of the machine even for users without specific programming experience. The user is guided through each operation step and the intuitive interface optimizes the entire work cycle. Furthermore, the tree structure and 3D visualization make fine-tuning the program easy to accomplish. - The most compact in its category

BLM GROUP offers the most compact footprint on the market. smallest footprint for all machine components for maximum efficiency in cutting complex geometry components.

- Type of parts

The machine can process a wide variety of parts types and shapes: bent tube, hydroformed, stamped, deep-drawn tube, and assemblies. The machine dynamics and the working area are optimized to process complex parts. - Overall dimensions

The compact footprint saves valuable floor space. - Focusing head

Designed to allow access to any location on the workpiece, whatever its geometry. Robot manipulation further expands capabilities and aids in reaching challenging areas on the part.

- Type of parts

Laser welding and cutting, better together or separated?

Equipping your 3D laser cutting system with a welding head means you can combine two processes in the same machine, using the same laser source to cut and weld two metal profiles.

Unlike other machines on the market, BLM GROUP has chosen not to equip LT-FREE with welding capability because:

- Using the same system to laser cut and weld means that one of these processes must necessarily be sacrificed to the benefit of the other. This is a disadvantage to productivity, which is further delayed when changing from one process to the other.

- Generally, the configurations of laser cutting machines are different from those of welding cells so a hybrid system will always be based on a trade-off.

Is LT-FREE really an opportunity not to be missed?

If you are considering buying a 5-Axis laser cutting system, discover the benefits you will get by introducing LT-FREE into your production facility:

- A specific cutting system for the tube world:LT-FREE is the only 3D cutting machine mainly designed for the cutting of curved and hydroformed tubes. It allows you to stand out from your competitors, being able to offer the same processes but at a much lower price with the use of robot handling and all the other advantages from the programming to starting production. LT-FREE will allow you to operate without reworking and secure maximum competitiveness.

- Flexibility: LT-FREE allows you to switch from the 3D IGES or STEP drawing to the cut part in an extremely short time.

- Experience on the machine: BLM GROUP has transferred more than 60 years of experience in tube processing and laser cutting into LT-FREE technology with Active Tools features to optimize the automatic cutting process and eliminate waste.