LT-FREE is the BLM GROUP 3D laser system for processing any three-dimensional profile, curved, deep-drawn, hydroformed, pre-welded, flat or printed sheet metal alike.

The machine is equipped with an array of features which make it capable of processing a wide variety of applications:

- From a 3D drawing in IGES or STEP to the finished part. The user-friendly machine interface allows you to import a CAD model and move to production simply and quickly. It’s an ideal feature for manufacturers with high-mix production and for making prototypes.

- Highly flexible and productive loading and unloading solutions like the dual shuttle tables or rotary table. Together with off-line programming, these solutions allow you to program a new part while the machine is still cutting the previous one to maintain your competitiveness even on medium-to-large production batches

- Using a handling robot means being able to manage cutting curved and hydroformed tubes in an entirely new way with no need for manual repositioning. It is ideal for processing tubular components, even of complicated shape, and to guarantee the highest standards of precision and productivity

In addition to the specific advantages offered by the machine, the LT-FREE is the best choice for your business because you are choosing the quality and guarantee of BLM GROUP products and services for your production

BLM GROUP: one of the major international tube processing partners

With more than 60 years of experience, the wide range of BLM GROUP solutions covers a broad spectrum of all tube processing solutions. That's not all. BLM also offers machines for bending wire and sheet metal laser cutting, as well as any three-dimensional profile.

Over time, BLM GROUP has not only developed machines, but sophisticated programming software and the ability to integrate the different technologies in an All-In-One principle.

What is All-In-One?

It is a software solution designed to integrate the various tube processing technologies. Here are some examples:

• In the case of a laser-cut and bent tube, All-In-One means being able to correct the laser cutting of the geometries on the tube, taking deformation effects of the subsequent bending process into account.

• In the case of tubes which are bent before being 3D-laser-cut, Artcut directly imports from VGP3D the waste produced by the bending process and takes it into account throughout the part programming process.

Some of the key programming software programs are included in the BLMelements suite:

- ArtCut: programming software for 3D laser systems

- Artube: software for programming straight tube laser cuts

- VGP3D: software for programming all BLM bending machines

- Protube: MES to manage production in Industry 4.0 perspective

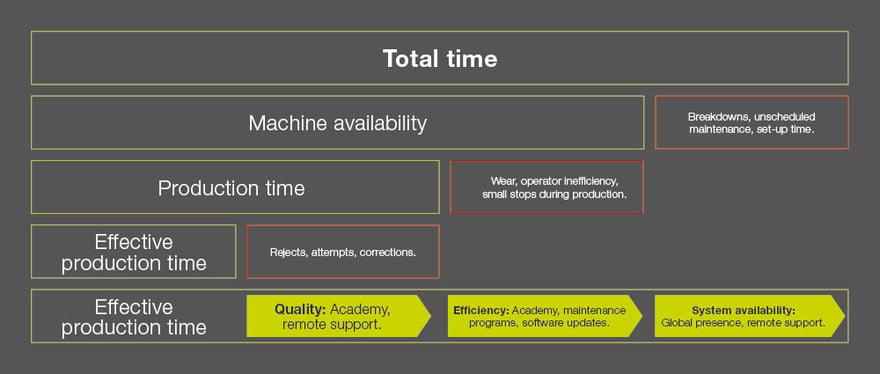

In addition, there is a wide variety of software and add-on modules for other technologies and for specific needs. BLM GROUP also offers a wide range of services aimed at maximizing your Overall Equipment Effectiveness:

- Remote support

- Maintenance plans

- Technical assistance and supply of spare parts worldwide

- Training programmes

- Customized packages specific to each customer

BLM GROUP: a family first and foremost

One of the greatest values of BLM GROUP is that of being a family-owned business. This factor has always been of great importance for product and service quality, as much today as it was 60 years ago. This is why:

- BLM GROUP is not a large, conglomerate group, it is led by a family that built the trust of its customers (and continues to do so) with the same care and dedication as when it began many years ago.

- Family businesses generally last for generations, this is to the benefit of customers who will always have a partner to rely on, that invests in R&D and is ready to suggest new ways to advance production, not to mention the availability of spare parts.

- As a family-owned business, BLM GROUP makes decisions quickly and effectively to adapt to market trends and provide solutions to its customers.

- For a family-owned business, prestige, reputation and trust are fundamental values that must be protected. For this reason, the quality of products and services must always be excellent.

BLM GROUP USA: Sales, customer care, team, organization

One of the important advantages of choosing BLM GROUP is the proximity of local staff, factory-trained at our headquarters in Cantù (CO) and Levico Terme (TN), Italy.

BLM GROUP is represented in the USA by its subsidiary BLM GROUP USA. which for 18 years, sells and services machines in the United States and Canada.

BLM GROUP USA has:

- Solutions Center for equipment demonstrations

- Application development

- Customer training

- Customer service and remote assistance call center

- Administrative offices

- Dedicated spare parts inventory

Forty-seven US technicians located in-house and regionally to provide prompt service response and resolution.

Twelve sales agents provide complete and competent support to guide you to the best solution to grow your business, improve your productivity, and expand into new markets.