Innovating is not only an exercise of ingenuity aimed at increasing your profit margin. Today more than ever, it is a necessity because the world is changing and with it are the needs of customers and the technological solutions to satisfy them.

From the structural point of view, Lasertube systems are an integral part of this technological change and are actively contributing to the innovation process of many companies bringing about major benefits:

- They can make any type of joint or node between pipes and/or beams of a structure with a precision and productivity impossible to achieve with conventional technologies.

- They can reduce the environmental impact of your production by implementing all-electric technology. They help decrease overall running costs, are an energy-efficient technology compared to traditional processes and Lasertube systems can exploit all the benefits of steel construction, from metal recycling to logistics and on-site assembly to the fullest.

- They generate an image of professionalism and prestige by improving working conditions for operatives and achieving a higher technological level of the manufactured parts.

Acquiring new orders, the first crucial objective

Already in itself, the benefits outlined above can increase your ability to acquire new orders and generate profit. However, it is also worth spending a few words on some of the intrinsic qualities of these systems that have a positive impact on your everyday work.

Ability to provide quick and accurate quotes

All Lasertube systems use the Artube CAD/CAM programming software, which simulates the entire work cycle and calculates the production time of each part quickly and accurately. Furthermore, with the Protube module, you can manage production orders and interface with your ERP system.

Ability to manufacture fast and at the lowest cost

The versatility, precision and productivity of the LT14 and LT24 and of all other BLM GROUP Lasertube systems are the key. The practical advantages of these characteristics:

- increase in the number of feasible parts;

- better precision and quality of the parts made;

- high productivity even for small and rapidly changing production batches.

Ability to rely on a system that is easy to use and program

With the LT14 and LT24, you can rely on simple and user-friendly programming, fully automatic material handling and machine set-up and easy system operation even for operators who have no experience with this type of technology.

These aspects, on the one hand, reduce costs and production time, and on the other, greatly increase precision and manufactured part quality with a considerable increase in profit margins for the user.

Lasertube for large diameter

The LT14 is the fully automatic Lasertube system for 3D laser cutting of profiles and tubular components from a minimum of 25 mm to a maximum of 355 mm in diameter and up to 18 m in length, for a maximum weight of 100 kg/m.

The LT24 is the fully automatic Lasertube system for 3D laser cutting of profiles and tubular components from a minimum of 50 mm to a maximum of 610 mm in diameter and up to 18 m in length, for a maximum weight of 300 kg/m.

The LT14 and LT24 Lasertube systems for large tubes and profiles are designed to accompany the process of innovation that is taking place in the construction world and other sectors and to be competitive by using tools and functions that many people do not yet have.

The remarkable versatility of these system allows the processing of round, square and rectangular section tubes, as well as open sections made of iron, mild steel, alloy steel and stainless steel, with no need for special and expensive equipment that must be replaced for each new job.

The main components of these systems are:

3D laser cutting head

With its five CNC axes, the 3D laser cutting head can work either orthogonally or inclined with respect to the surface of the tube. This means you can make orthogonal cuts, inclined cuts, chamfers, semi-chamfers and more, to create any type of interlocking with tubes and/or profiles.

This technology also makes later welding operations easier. The laser makes cuts with high geometric precision and no need for later surface grinding operations.

The 3D laser cutting head can work either orthogonally or inclined with respect to the surface of the tube.

The 3D laser cutting head can work either orthogonally or inclined with respect to the surface of the tube.

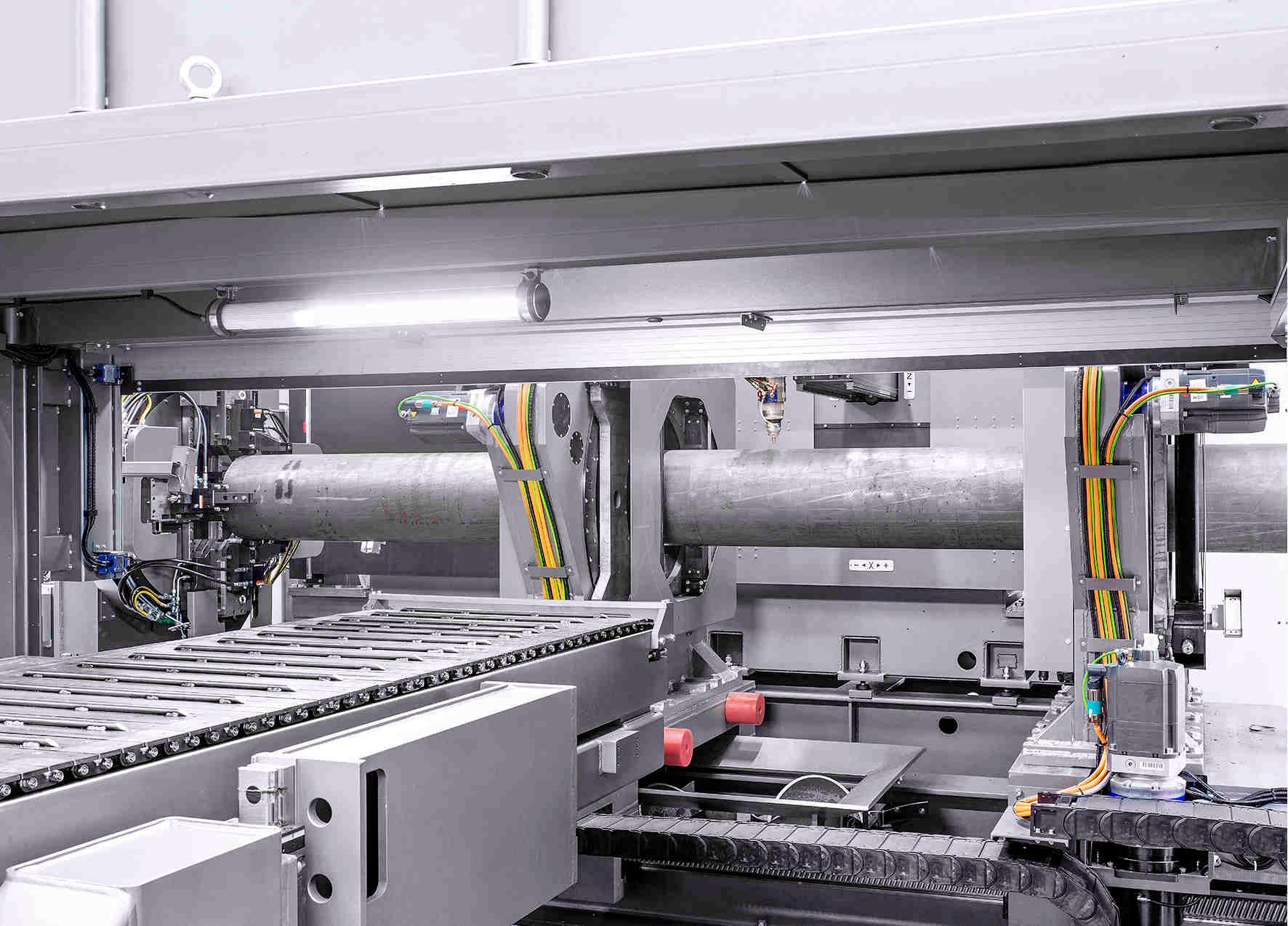

Spindles

An important contribution to precision in LT14 and LT24 systems is given by the workpiece handling functions implemented by three all-electric spindles with automatic set-up functions designed to protect light-weight tubes from crushing and guarantee a firm hold of heavier tubes.

The position of the spindles during cutting operations is managed automatically to minimize bar movement. The two spindles have the double function of making the tube sliding and clamping it. In this way, the bar is never completely free and the cut is more precise.

The cutting head automatically switches from one side to the other of the spindles and can cut the tube in three different positions:

- Head cutting: The head works downstream of the through spindles on the final part of the bar.

- Central cutting: The head works on the central part between the two through spindles.

- Tail cutting: The head works upstream of the through spindles on the initial part of the bar.

In this manner, the cutting head can work on the whole length of the tube, without producing scrap and without the spindles needing to rework the part.

Workpiece handling is performed by three all‑electric spindles with automatic set-up features on LT14 and LT24 systems.

Workpiece handling is performed by three all‑electric spindles with automatic set-up features on LT14 and LT24 systems.

Active Tools

Created to guarantee productivity, safety, quality, automation and ease of use, Active Tools are cutting-edge technical solutions to achieve the best results in less time, regardless of the operator's practical experience. The following Active Tools can be fitted on the LT14 and LT24:

- Active Piercing: This increases productivity on medium-high thickness parts by detecting the breakthrough of the material and acts as process control avoiding the drift during of laser cutting.

- Active Focus: This function improves cutting quality by automatically adjusting the focus according to material and thickness.

- Active Mail: This function provides useful support for managing maintenance. It provides information on the activities to be performed and sends an email containing the maintenance report.

- Renishaw: Measuring system directly on the cutting head for centering the machining operations.

- Tap & Drill: This unit has an automatic tool store and function for monitoring tool integrity. It can drill and tap threaded holes in sequence from M3 to M16 also using the Flow Drill device.

The technological developments over the years make the LT14, the LT24 and all the other BLM GROUP Lasertube systems stand out distinctively from the less performing systems.

All operations from project to product with a single software tool

While the LT14 and the LT24 can replace the numerous machining operations, some of which are manual, needed to create the finished product, Artube, the CAD/CAM programming software with which they are equipped, simplifies programming of the entire work process from CAD to the CAM machine programming environment.

Developed over the years, Artube is the most advanced software on the market for the programming of laser tube cutting systems. It offers a range of features and of additional software packages that simplify and enhance work in multiple fields of application.

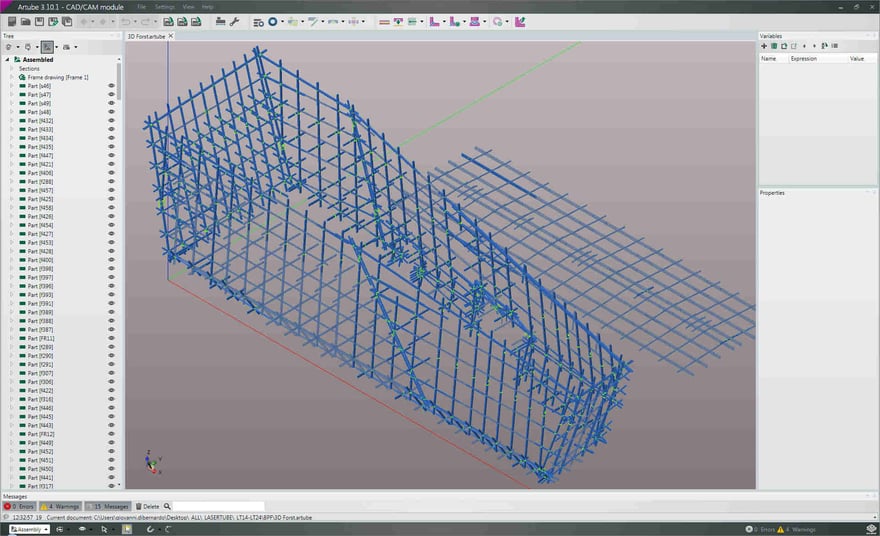

As CAD/CAM software, Artube creates the part program (CAM) and allows you to create single parts and even frames and complex structures from scratch (CAD). What is more, joints between tubes are created automatically using a wide library of supports and joints.

Once a part has been imported or modelled in the Artube 3D CAD environment, the software automatically creates the best tool path, precisely defines the correct inclination of the head for inclined cuts and applies the optimal parameters for cutting along the entire path.

All operations are represented graphically and distinctively color-coded in the 3D graphics of the laser cutting path. This type of representation helps to understand how the part will be processed, to the advantage of production safety and programming rapidity, exactly, simply and immediately.

Artube is the most advanced software on the market for programming laser tube cutting systems.

Artube is the most advanced software on the market for programming laser tube cutting systems.

In the structural field, Artube can import IGES, STEP and IFC (Tecla) files, making all the elements of the structure immediately available to the operator. As a result, each element can be extracted, modified as needed and converted into the machine program ready for processing.

This cancels out all the time needed for traditional IFC file conversion into STEP, IGES and X_T and reduces design and programming time with a considerable advantage in terms of cost and flexibility.

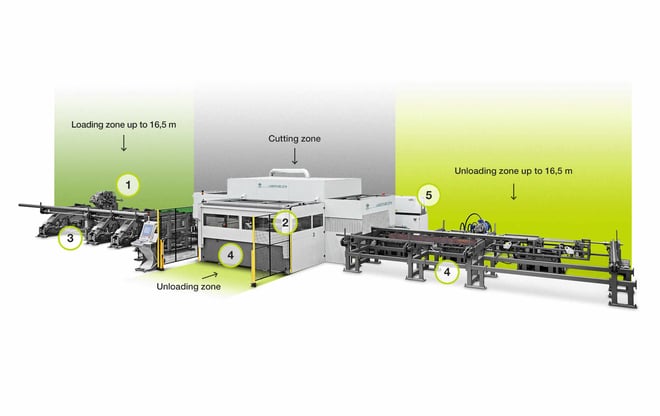

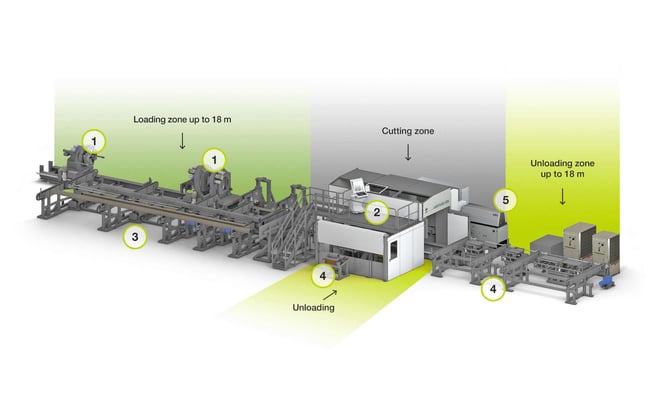

Automatic loading and unloading

LT14 and LT24 have special fully automated loading and unloading systems for the handling flows into and out of the system, fast and safely.

The finished parts are unloaded continuously without interrupting the cutting process. The unloading device:

- Extracts shorter parts, up to 3.2 meters long using a conveyor belt inside the cutting enclosure.

- Extracts longer parts using unloading chains located downstream of the cutting enclosure.

The chain loading device is compact and accommodates tubes and profiles of different shapes and size with no need for adjustments or additional equipment. Parts of different section and size can be arranged in sequence and without an obligatory position on the loader. Each bar will be separated and loaded without manual intervention, then the machine will pick the parts and handle them appropriately. In this way, the material handling flows to the production area do not need to be changed and no further investments is necessary.