LASTTS (LASer cutting Technology for Tubular Structures) is the European project that studies the use of laser-made passing through joinery between tubes and beams. The goal is to increase the efficiency of the construction sector.

Construction industrial sector and environmental sustainability

Globally, the construction sector exerts a significant environmental impact, contributing to 40% of overall carbon dioxide emissions, and it is estimated that as the population increases, about 2.5 billion more people by 2050, we will have to build a lot of new infrastructure in the future: bridges, renewable energy facilities, buildings, stadiums, etc.

Therefore, improving efficiency in the construction sector is a key objective to ensure a sustainable future. To achieve this, it is necessary to adopt comprehensive solutions that take into account the choice of materials, construction methods and design.

In this article you will learn about one of these solutions: the interpenetration joint, which is also the subject of the study of the European project LASTTS.

This innovative method of connecting tubes and structural profiles, which can only be efficiently achieved with laser cutting technology, aims to reduce the use of material, lighten the structure and speed up installation.

At the bottom of the article, you can watch the seminar speech given by Prof. Alper Kanyilmaz of the Politecnico of Milan: "Laser cutting in structural solutions", promoted by BLM GROUP and Fondazione Promozione Acciaio, where the professor explains this innovative solution in detail and presents some interesting case studies.

Watch the lecture of Professor Alper Kanyilmaz's from Politecnico of Milan.

To learn more about the advantages of building with steel, we recommend you reading this article: Building with steel: the real benefits of today and tomorrow.

Additionally, if you want to learn more about the latest technologies for the production of steel structural components, we recommend this article: Architecture: new technologies for steel constructions.

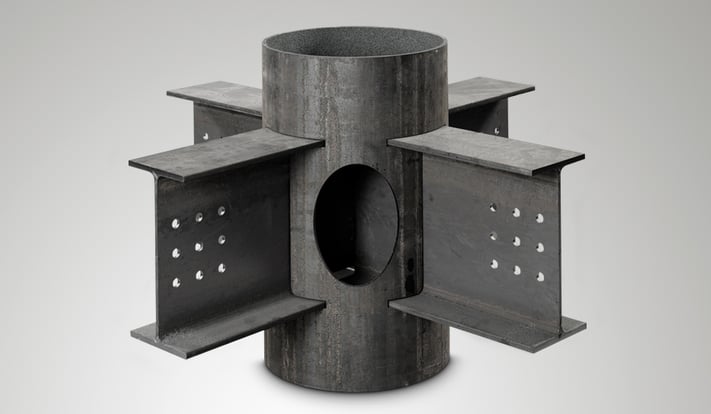

Example of a interpenetration joint for structural purposes made with laser cutting technology.

Example of a interpenetration joint for structural purposes made with laser cutting technology.

The keystone: the idea of interpenetrating joints

Subject of study of two European projects: first LASTEICON (Laser Technology for Innovative Connections in Steel Constructions) and then LASTTS (LASer cutting Technology for Tubular Structures), the idea of passing through joinery aims to solve the problem of fragility that arises when a structural element is welded on the surface of a tube.

To overcome this problem, manufacturers are forced to increase the complexity of assembly through additional reinforcement elements such as: welds, bolts, plates, etc., which not only weigh down the structure but also increase construction times and costs.

The European projects LASTEICON and LASTTS demonstrated how passing the element inside the beam increases the strength of the joint without weighing down the structure with additional reinforcement elements.

The result is lighter structures and shorter installation times.

Why Laser Cutting

It would be impossible to switch from a standard joint to a passing through joint without the use of laser technology, given the limitations of traditional technologies in terms of cutting inclination, precision and efficiency.

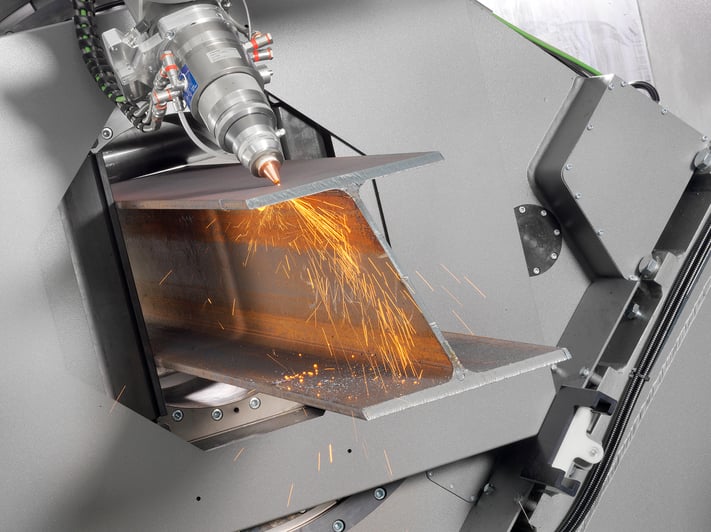

Cutting a HEA beam with the LT24 lasertube system for large tubes and profiles.

Cutting a HEA beam with the LT24 lasertube system for large tubes and profiles.

In order to create passing through joints, it is necessary to perform cut and chamfers on the workpiece with very high precision and a well-defined inclination of the cutting edges.

To create the passing through joints needed for their experimental tests, the LASTTS project used the LT24 laser cutting system for large tubes and profiles from BLM GROUP, a company that is part of this research consortium.

sistema di taglio laser per tubi e profili di grandi dimensioni LT24 .

sistema di taglio laser per tubi e profili di grandi dimensioni LT24 .

Capable of automatic 3D laser cutting of tubes and profiles up to 610 mm in diameter, LT24 can produce structural components ready for assembly and welding on site, which do not require further fine-tuning, with a very short cutting time that in any case is predictable already in the design phase.

The LASTTS project presented by Prof. Alper Kanyilmaz of the Politecnico of Milan

The idea behind the European research project LASTTS is to validate, through experimental tests, the use of passing through structural joints made by laser cutting of tubes and beams. The aim is to make the construction industry more efficient and sustainable.

Below is the complete speech by Prof. Alper Kanyilmaz of the Politecnico of Milan that was collected during the conference organized by Fondazione Promozione Acciaio and BLM GROUP entitled "Laser cutting in structural solutions".

This work is part of the EU-RFCS-709807 project LASTEICON “Laser Technology For Innovative Connections In Steel Construction”, and EU-RFCS 101034038 project LASTTS “Laser Cutting Technology for Tubular Structures”. Views and opinions expressed are however those of the author(s) only and do not necessarily reflect those of the European Union or Research Fund for Coal and Steel. Neither the European Union nor the Research Fund for Coal and Steel can be held responsible for them.

Watch the other seminar speeches:

Turning a tube and steel stockholder into a metal service center

Speech by Massimo Fasolo, Head of the Technical Office of the Laser Department of SICAM S.p.A. and Luca Prasso, Area Director at SICAM S.p.A.

3D structural BIM and other innovative technologies for construction

Speech by Paolo Sattamino, Technical Director of Harpaceas Srl.

3D laser cutting machines for tubular profiles

Speech by Cristian Signorotto, Technical Director of Officine Bertazzon.