What business leader or production manager does not want the most modern and advanced machinery on the market in their plant?

In metal cutting, there isn’t necessarily one technology better than another because the effectiveness of each one depends on the type of production for which it is used.

However, there are a number of questions that can guide a manufacturer in the search for the right technology:

- How can I be more productive?

By using features, functions, hardware and/or software systems that can support production at every level. It is therefore essential to assess which of these elements will have the greatest impact on your processes in terms of productivity. - How can I save money?

Look for a technology that allows you to save time, energy, labor, and allows you to eliminate all unnecessary steps, such as storage of semi-finished products, long work cycle programming procedures and/or processing tests. - Can I bear the cost?

Before purchasing a new system, you need to define the depreciation plan, with the costs and benefits of introducing a new technology.

Discover how to choose the right technology for your production plant

Bent tubes, pressed, deep-drawn and hydroformed sheets - What does precise cutting mean and how can I achieve it?

In metal cutting, in the specific case of bent pipes, stamped, deep-drawn and hydroformed sheets, the level of precision required depends essentially on two factors:

- The application fields: For example, aerospace and defense are low-volume, high-variation industries which require high precision cut quality.

- Final part use: A different degree of precision will be required according to the task the end part is called to perform.

|

|

|

|

| Example of preformed titanium sheet for the aerospace sector | |||

It is worth considering that achieving a given level of precision when cutting flat sheet metal or complex shaped 3D profiles is not the same and this may also vary according to the system used.

Think of 3D laser cutting, for instance. The profile and cutting geometry being the same, the process performed with a 3D laser head mounted on robots will be much lower than that of a laser head mounted on a five-axis system. Consequently, the cutting profile will have a very different quality in the first and second machine configuration.

The CNC used for moving the head is not the only feature to influence the cutting process. An array of other factors plays a fundamental role in laser cutting:

- Power

- Material to be cut

- Service gas

- Management of cutting parameters

Find out more about laser metal cutting

The three objectives to aim for: productivity, reliability and quality

It is no mystery that these three important objectives must always be combined to achieve successful production. For this reason, many companies choose suppliers that offer not only high-productivity systems capable of performing high-quality machining but also highly reliable systems, in which downtime and maintenance operations are minimized.

A manufacturer must have a machine that offers maximum uptime and reliable performance to handle any workload requirement.

|

| 3D laser cutting combined with robot handler |

Many factors play an important role in this:

- Quality of components: It is important to choose a supplier who is able to guarantee the quality and origin of all the materials used.

- Design that reduces problems or failures and minimizes and simplifies maintenance interventions: A supplier that's earned a long-standing reputation for exceptional reliability and maintainability can rely on an exceptional team of technicians and engineers.

- Use of technologies with proven reliability: Many products and technolgoies evolved over time not only based on performance, but also reliability. It was precisely this quality that made it so accepted. A classic example is the fiber laser, which offers lower operating costs and maintenance requirements because it lacks all the moving parts typical of CO2 lasers.

Consider a partner driven by productivity and reliability as main features behind their machine design.

Find out how to choose the right partner for your production

What is the right technology for the production of today and tomorrow?

By implementing a new metal cutting technology, many important factors must be taken into account:

- The need to make production ever more flexible

- Energy saving and consideration for the environment

- Minimizing floor space reuirements

- Reduced maintenance on the machine

- Reduction of labor

- Reduction of intermediate steps, handling and storaging of semi-finished parts

As mentioned, laser cutting systems can be the right innovative solution for many manufacturers.

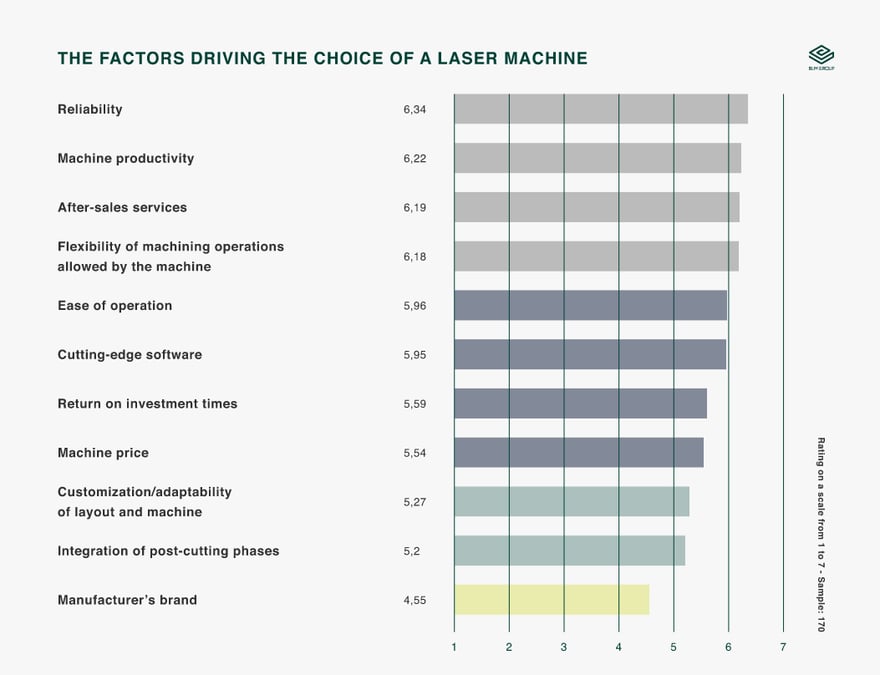

The following table shows some results of the Go-To-Market analysis: Increasing effectiveness in value proposition, conducted from April to May 2017 on a total sample of 397 units (BLM Group laser customers / competitor brand laser customers / non-laser users). As you can see, there are many common factors that drive the choice of a laser machine.

Flexibility: what the market demands

Production flexibility means the ability to adapt quickly to market needs.

It is increasingly necessary to be able to adapt your production quickly to the requests of customers who expect shorter lead times and reduced prices.

That's why you need intelligent technology that can:

- Predict, simulate and calculate all production parameters

- Adapt and facilitate each stage of production process

- Reduce preparation and set-up times when switching form one production to another

A technology that is first and foremost capable of making time for your operation to predict, plan and think about the next production.

Choosing the right metal laser cutting partner

Typically, when it comes to choosing a manufacturer of metal laser cutting machines, a wide range of possibilities opens up: Trumpf, Prima Power, BLM GROUP... They all offer good solutions for five-axis laser cutting.

However, consider the following factors when comparing maufacturers:

- Machine and components quality

- Process quality and precision

- Application and features of the required processing

- Training and support services

- Qualità e precisione della lavorazione

The best advice is to choose a manufacturer whose goal is to establish a partnership with customers.

The right manufacturer must:

- Know how to guide customers to select the correct product for their manufacturing needs (current and future)

- Be there when the customer needs training

- Have a strong service organization capable of rapid support - onsite and remotely.

Finally, choosing a manufacturer with local staff that speaks your language, with experience and the ability to offer assistance and training packages specific to your needs is certainly a key point to take into account when choosing a partner.