B&J Inc. was originally incorporated in 1975 by the company’s founder as a Machine Shop. B&J was soon recognized for its high-quality work by its customers, and the opportunities allowed the company to expand its operations by adding sheet metal fabrication capabilities as its main source of revenue. B&J, Inc manufactures assemblies/sub-assemblies & components for various industries such as: Gaming/Entertainment, Water Utilities, Automotive, Medical, and Fitness industries, to name a few.

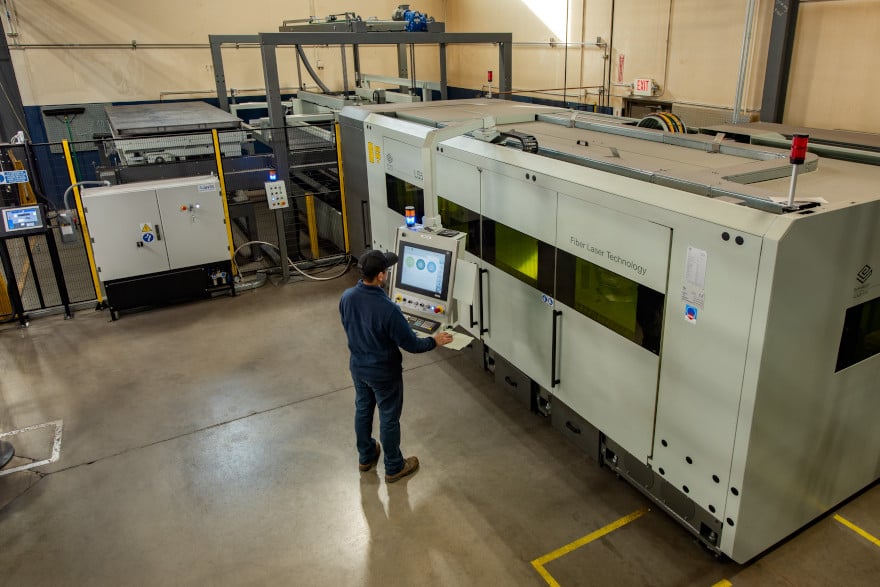

Gregg Fisher at B&J Inc. facility.

Gregg Fisher at B&J Inc. facility.

He soon invested in semi-automated lasers, fully automated punches, robot press brakes, and robotic welding to join the existing CNC machining centers – all helping keep the overhead low and the productivity high.

Part of B&J’s success is a result Fisher’s goal to stay ahead of change at all times. Fisher recognized the paradigm shift in the industry, where demand was increasing for more industrial assemblies and sophisticated “one-offs” were becoming increasingly common.

The goal became for B&J to function as a single source supplier to its customers. Fisher then decided to expand the company’s capabilities further by adding a tube laser system. After spending several months researching and learning (in great detail) about the tube lasers from all major manufacturers in the industry, Fisher decided to choose BLM GROUP’s LT7.

During the same period, Fisher was in search of the right Sheet Laser system for their operations in order to upgrade one of their old sheet lasers. In addition to the LT7 Tube Laser, he also decided to purchase BLM GROUP’s LS5-3015 Sheet laser.

Besides the technology, the modular design, accessibility, and flexibility in configuration of BLM GROUP’s sheet laser captured Fisher’s attention. Fisher says the LS5 was the only machine in the market with the configuration that he wanted. BLM GROUP’s LS5 sheet laser made its debut at B&J in May of 2019.

The big change for B&J with the LS5 was the move from CO2 to an 8kW fiber laser. This presented some additional startup costs for plumbing the shop for bulk nitrogen, which was required for both of the new machines. But, these costs were offset by the speed and reliability of the fiber laser, which actually created the ability to take on more work in the shop.

BLM GROUP’s LS5-3015 Sheet Laser System with Automatic Sheet Loading/Unloading system, at work in the B&J factory.

BLM GROUP’s LS5-3015 Sheet Laser System with Automatic Sheet Loading/Unloading system, at work in the B&J factory.

The LT7 tube laser soon followed the LS5 delivery and was commissioned in June of 2019. The B&J team received a week of training on the equipment at the BLM GROUP technical center in Novi, Mich. And, Fisher acknowledges the transition to running the equipment on B&J’s floor was pretty easy.

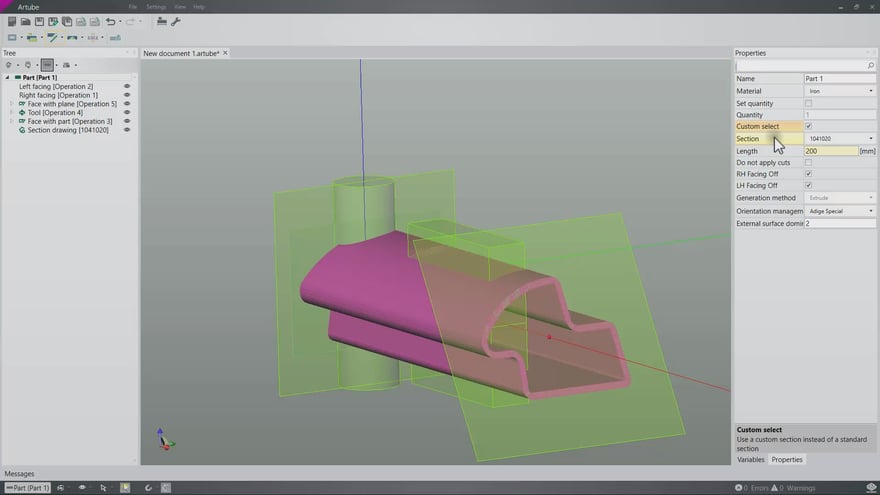

Artube: BLM GROUP’s tube laser programming & machine/production management software.

Artube: BLM GROUP’s tube laser programming & machine/production management software.

Fisher states that one of the strongest values of the LT7 for B&J is the Artube, software, which Fisher says is, “crushing it!” with incredibly simple setup, as well as the ability accurately & swiftly estimate a job. “When you’re competing in a world of one-offs, people want an accurate answer very quickly. With the BLM GROUP’s Artube software, we can get an accurate quote for a job within minutes, which is hugely helpful in the sales process.”

LT7 Processing 3-1/4” OD Tube at B&J, Inc.

LT7 Processing 3-1/4” OD Tube at B&J, Inc.

Typical components being processed on the system are usually comprised of steel-tube varying from .500" SQ to 6.0" SQ in size, such as one-off custom pallet designs for repetitive lifting procedures used in packing and assembly operations, or industrial track equipment for vehicles.

The LT7 has allowed B&J, Inc to keep more work in house and to bring in new work. Within just the first six months after installation, B&J noticed a significant business growth.

BLM GROUP’s LS5-3015; 8 kW Fiber Laser System, processing Stainless Steel parts at B&J, Inc.

BLM GROUP’s LS5-3015; 8 kW Fiber Laser System, processing Stainless Steel parts at B&J, Inc.

Additionally, Fisher added that the new LS5 Sheet Laser system has allowed them to expand their operations towards processing non-ferrous materials, such as aluminum, copper and brass, where he believes there is also huge room for growth.

“We’ve been in hiring mode ever since installing this equipment,” he commented. “It’s both exciting and stressful.”

To help with the increasing volume of work, B&J has hired a Lean Manufacturing Coordinator for the first time in company history to help level out the scheduling and ensure that work gets out the door as promised.

The laser-cut edges are ready for welding, without any additional weld prep. The tube laser and software offer diverse fab-form and locking tab capabilities that can help simplify and speed up operations. The precision of the tube lasers enables parts to bend or even snap together easily to simplify welding operations.

This article was published also in: Fabricating & Metalworking and Metal forming & fabricating.