Whether you are a subcontractor or an OEM, you hear about efficiency, flexibility, and productivity every day. These three buzzwords accompany the productive life of every company and are fundamental in today's market.

Sure, having a goal is crucial, but how do you know if you're moving in the right direction? How can you calculate the level of efficiency, productivity, and flexibility of your production system? More importantly, how can you improve it? By how much and what tools are needed?

The Overall Equipment Effectiveness of a production system

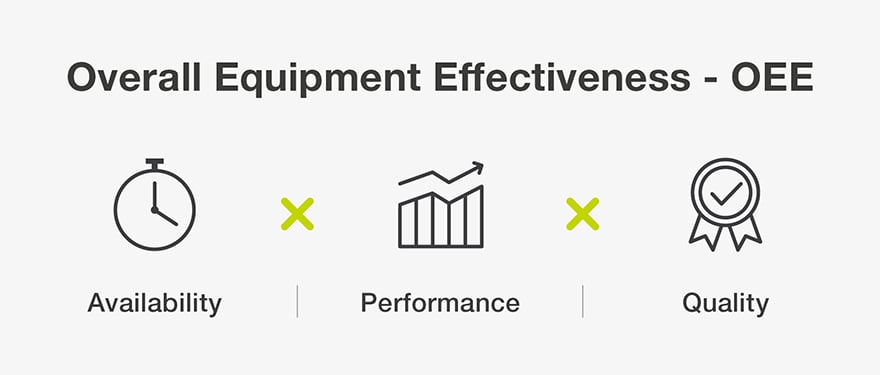

The metric that best summarizes the level of efficiency of a production system is called OEE, or Overall Equipment Effectiveness.

OEE is a globally recognized key performance indicator that measures how well a manufacturing operation is utilized compared to its full potential, during the periods of operation. It identifies the percentage of manufacturing time that is truly productive:

- plant availability (the ratio of system uptime and the total available time);

- production quality (the ratio between the number of parts made that meet specifications and the total number of parts);

- productivity (the ratio between working speed and design speed).

The OEE is calculated by multiplying the availability, quality and productivity of a production facility.

The OEE is calculated by multiplying the availability, quality and productivity of a production facility.

The main loss factors

It is important to note that as a metric of the entire production chain, the value is affected by the individual efficiency of each machine involved and in particular of the less efficient machines.

The efficiency of a mechanical system is the product of the efficiencies of the single machines working in sequence. From here, it is easy to see that if one of these values decreases consequently, the overall efficiency decreases, moving away from the virtuous efficiency value of the other systems. A chain is only as strong as its weakest link and this rings true for the OEE as well. If the productivity, availability or quality percentages of one of the machines are clearly lower than the average of the others, the overall value of the OEE will drop significantly. That particular equipment or operation will become a bottleneck for the entire production cycle.

The main loss factors that impact the OEE of a system are

:

- Unscheduled downtime, which includes equipment failures, operator illness or injury, or other types of unplanned interruptions;

- Scheduled downtime, such as set-up operations, changes of tools or fixtures, manual adjustments, maintenance, cleaning, etc;

- Small production stops, for checks and measurements, for instances;

- Speed reductions that can occur if for some reason the production speed is lower than planned, such as inexperienced operators working on a very complicated system to be used, sub-optimal working conditions, etc;

- Defects that have to be corrected by additional operations, such as burrs that need to be removed, chamfers that need to be made for downstream welding operations, etc;

- Scraps, that is, the parts that cannot be recovered and are wasted, taking with them the value of the material and the time in previous processes.

Lasertube systems significantly reduce these six loss factors and below we will see how.

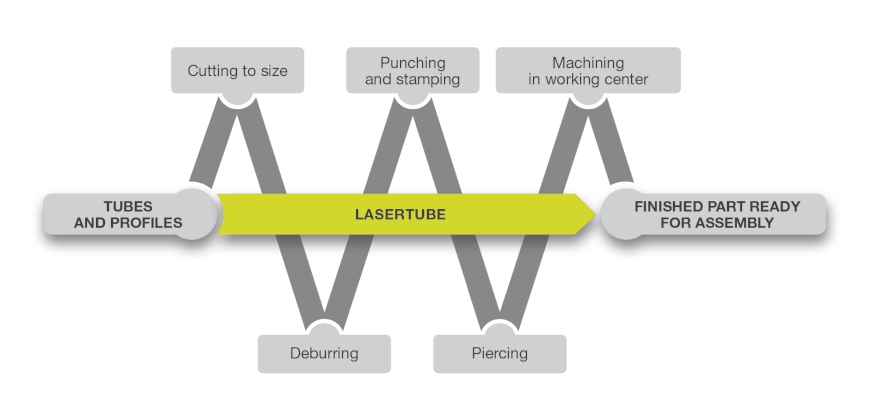

A Lasertube can replace many traditional processes, shortening and simplifying the production chain and consequently improving OEE.

A Lasertube can replace many traditional processes, shortening and simplifying the production chain and consequently improving OEE.

Cutting complexity to increase OEE

One of the main strengths, that is particularly evident when working on large diameter tubes both in the construction sector and for manufacturing farming machinery, excavation machines and industrial vehicles in general, is the possibility of replacing many of the traditional processes, such as cutting, drilling, grinding and milling, with laser cutting.

The laser allows high-precision parts to be cut with, where necessary, holes or notches to create supports and joints between tubes, beams and profiles, to simplify assembly operations or connection chamfers to make perfect welded joints in compliance with regulations. As the number of operations and machines involved in the production chain decreases, the loss factors decrease proportionally, especially when it comes to obsolete equipment or no longer necessary manual work carried out on-site.

Simplicity is the Keyword

Simplicity is key to raising the overall level of efficiency of a plant or production system. With Lasertube systems, this concept is expressed in various ways:

Simple programming: when building large structures, for example, you may need to make many different parts from tubes or profiles. CAD/CAM software, such as Artube, allows you to import the IFC file of the structure, break it down, modify the individual components, if necessary, and send the program to the machine very fast.

Simple set-up and production changeover: All-electric technology and no manual adjustments or specific equipment play an essential role in this context.

Automation: when it comes to large tubes and profiles, automating the loading and unloading operations is a considerable added value in terms of logistical and organizational simplicity, but more importantly operator safety.

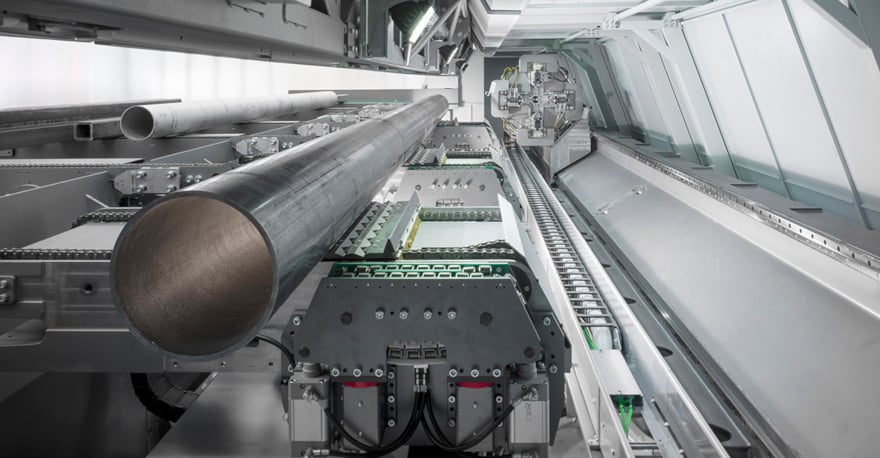

The laser cutting systems for tubes and large profiles allow the loading of bars of different shape with no need for adjustments or dedicated equipment and without a specific order or location.

The simplicity of use of the Lasertube systems makes it possible to reduce, and in many cases, even eliminate scheduled downtime, increasing the OEE and ensuring greater production flexibility.

LT14 FIBER loading system, tubes are loaded with no need for adjustments or dedicated equipment and without a specific order or position.

LT14 FIBER loading system, tubes are loaded with no need for adjustments or dedicated equipment and without a specific order or position.

Safety is efficiency

We've already discussed how the loss of efficiency of just one system or machine in a production chain substantially impacts the entire process, which is why safety is so important. In addition to being a worker's right, it has a major impact on the efficiency of a company.

The Lasertube systems, like all the other machines made by BLM GROUP, are equipped with the necessary devices to ensure that the system complies with regulations and at the same time maintains the highest standards of productivity.

For example, in the laser cutting system for tubes and large profiles LT14 FIBER, the laser cutting is performed in a safety-interlocked enclosure, inaccessible to the operator. A double partition allows loading the entire bar and transfer of the processed parts to the unloading area without having to switch off the laser.

In the LT14 FIBER laser cutting system for tubes and large profiles, the working area is completely sealed in a Class 1 safety enclosure.

In the LT14 FIBER laser cutting system for tubes and large profiles, the working area is completely sealed in a Class 1 safety enclosure.

Quality of services essential for OEE

Although the qualities introduced are of paramount importance for good OEE (reduce downtime, eliminate inefficiencies and improve product quality), it is essential to have on-site or remote support services, training for your operators, and scheduled maintenance.

BLM GROUP can offer a wide range of services for company productivity: scheduled maintenance contracts, remote, augmented reality and on-site assistance services, training with the BLM GROUP Academy, all supported by an extensive network of regionally-located service centers all over the world.

Discover all the services that BLM GROUP can offer you.