This is the age of integration, of the All-In-One to reduce operations and optimize production. We want to have everything under control, constantly measured and compared. We want all the information stored in an organized manner because we do not know when we are going to need it again, but we know that we will. We are always on the lookout for more and more sophisticated tools to manage a growing complexity and demand.

Beyond a shadow of a doubt, smartphones are one of the most striking examples of a multifunctional tool. These devices are capable of performing a thousand of activities, supporting our memory, protecting our deadlines, a magic wand capable of saving us from the many daily stumbling blocks.

Beyond a shadow of a doubt, smartphones are one of the most striking examples of a multifunctional tool. On our smartphone today, we can also perform augmented reality diagnostics on production systems with a simple application such as Active Eye.

Beyond a shadow of a doubt, smartphones are one of the most striking examples of a multifunctional tool. On our smartphone today, we can also perform augmented reality diagnostics on production systems with a simple application such as Active Eye.

Smartphones are only the latest multifunctional tool that have influenced our daily activities. Looking back, the tool that perhaps most of all associate the concept of multifunctionality is the Swiss Army Knife, the famous, little tool with an iconic white cross printed on a red background.

Its invention dates to1890, when the Swiss army asked for a tool capable of opening cans of food, dismantling weapons, etc. American soldiers also adopted it as standard equipment immediately after Second World II. But since the German name "Schweizer Offiziersmesser" was a bit of a mouthful, it became known to everyone simply as "the Swiss Army Knife"..

The name is a registered trademark, and despite the many imitations, it still remains in the collective imagination the original and the most appreciated.

Whether it is a matter of a few specific functions or incalculable amounts of applications all contained in a single tool, there is no doubt that it becomes easy to use when its benefits are immediate, and its advantages can be measured by cost and time savings.

BLM GROUP Lasertube systems play a similar role in manufacturing and especially in the tube processing sector.

At the right power, a laser beam moved with precision and remarkable speed along the surface of a metal tube can make a variety of applications in the most diverse industries.

Find out more about laser history.

At the right power, a laser beam moved with precision and remarkable speed along the surface of a metal tube can make a variety of applications in the most diverse sectors.

At the right power, a laser beam moved with precision and remarkable speed along the surface of a metal tube can make a variety of applications in the most diverse sectors.

Slim aluminum tubes that will become part of a designer object or large steel sections for supporting a bridge alike, laser can easily make cuts to size, geometries of any shape, markings and chamfers, all on the same system. The machined edges are clean and precise, the heat alterations - critical for later welding operations - are negligible and production quality is constant and independent from the operator's experience.

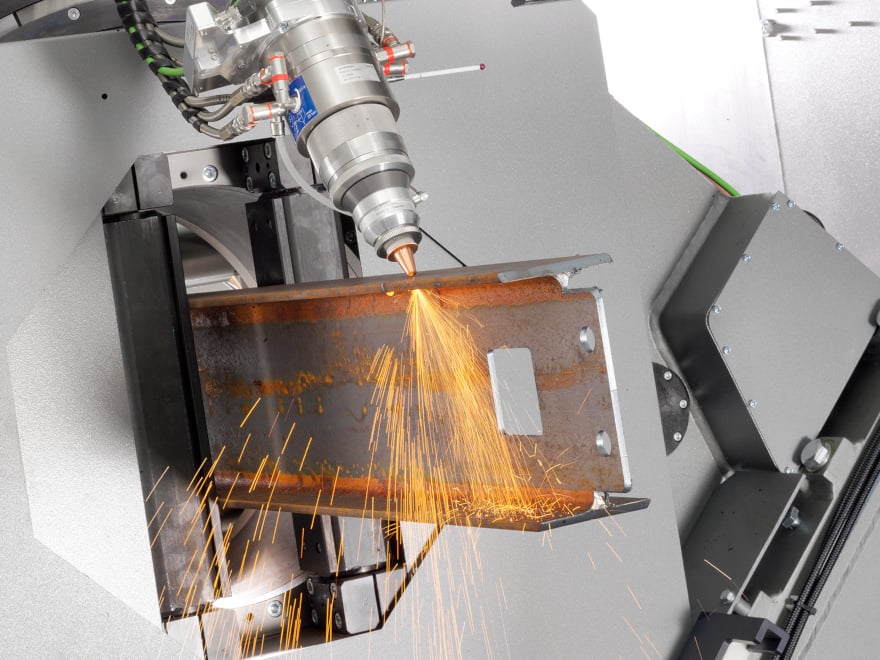

Laser cutting of IPE beam with LT14 laser-cutting system for large tubes and profiles.

Laser cutting of IPE beam with LT14 laser-cutting system for large tubes and profiles.

No need to use several systems to carry out all the required operations: cutting to length, deburring, milling, edge grinding, and marking.

The laser makes precise cuts that leave the processed edges smooth and free of burr. No handling and re-arrangement between one machining operation to the next, which is often a source of errors, is needed. No space occupation for intermediate steps. No dependence on the experience of the different machine operators. No need to check the quality of semi-finished products several times to maintain the efficiency of each operation.

Everything is solved in a handful of seconds (the ones needed to make each part), with a single machining operation, repeatable and error-free.

.

Bend cutting on square profile tube with clamping inserts.

Bend cutting on square profile tube with clamping inserts.

These advantages become even more important when compared to the trend in the manufacturing world to produce smaller and smaller batches to meet the increasing need for customization.

No more continuous mechanical retooling to adapt each machine to the new batch to be produced. No more different programming environments to set the necessary parameters each time.

A single CAD/CAM design tool that graphically includes the entire design of the part and sends it to the machine in the form of a machining program.

Bend cutting on special profile tube for window frames.

Bend cutting on special profile tube for window frames.

This is the ID of a Lasertube, an effective multifunctional tool for any industry and application in which it has been used. Thousands of customers worldwide are well aware that they have been able to make their business grow, gaining capabilities and capacity.

Easy to use, it takes up much less space than the many tools it replaces, it can be used carry out many operations with a single operator - and do it fast. Just like the little knife mentioned above.

Conclusions

Although a Lasertube has not yet joined the collections at the Museum of Modern Art in New York (MoMa) or the Museum of Science and Technology in Munich (Deutsches Museum), unlike the famous Swiss Army Knife, be sure that there are many objects that BLM GROUP Lasertube’s make and that have become icons of design and manufacturing excellence everywhere in the world.