Someone not familiar with the tube bending process is unable to imagine the complexity of maintaining the bending tool sets and using them to meet the production department’s requirements. This complexity is further multiplied when using different tube bending machines with different characteristics and needing sets to be tooled in time, whether the production batch is small or large.

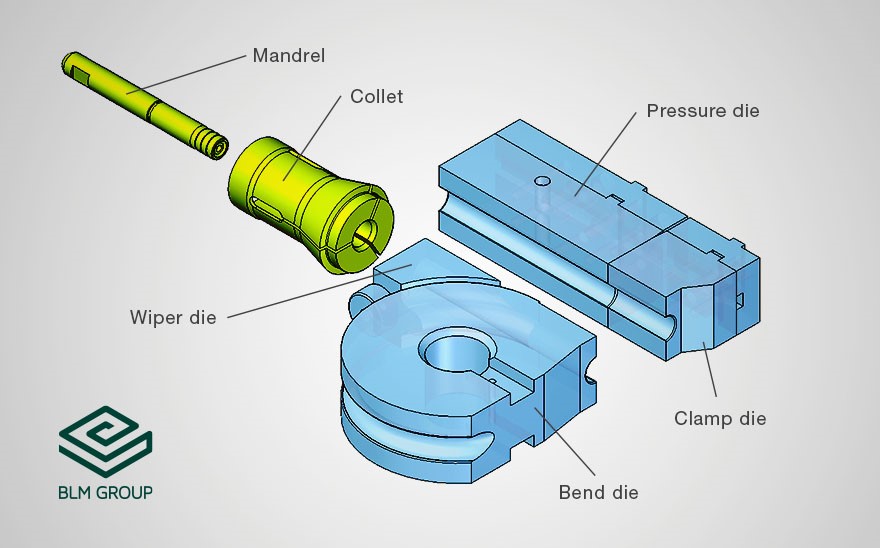

The components of a tube bending tool set and why they are so many

A tube bending tool set consists of the following main components:

Bend die

The bend die is the part of the tooling set in which the tube is bent on, its radius corresponds to the CLR (Central Line Radius) of the curve that will be made. The size of the grow is defined by the outside diameter (OD) of the tube.

Clamp die

The clamp die is the part of the tooling set which clamps the tube. The size of the grow is again defined by the outside diameter (OD) of the tubeIl tassello di bloccaggio è l’elemento che blocca il tubo contro la matrice: anche per esso, la dimensione della cavità che accoglie il tubo durante la curvatura è definita sulla base del diametro esterno di quest’ultimo.

Wiper die and pressure die

The wiper die and the pressure die of the tooling set sustains the form of the tube against wrinkling or fattening during the bending process. The size of the grow is also defined by the outside diameter (OD) of the tube.

Mandrel

The mandrel is the part of the tooling set which internally supports the tube. Its diameter is defined by the internal diameter (ID) of the tube.

Collet

The collet is the round clamp that grasps the tube, rotating it and moving it forward or backwards. The outside diameter of the tube that can be grasped is dependent on the size of the collet.

Main components of a tube bending tool set: mandrel, collet, wiper die, pressure die, bend die and clamp die.

Main components of a tube bending tool set: mandrel, collet, wiper die, pressure die, bend die and clamp die.

Referencing the list above, it is clear that one may have a series of different components for a specified outside tube diameter (OD).

Adding to the complexity, there are two main types of mandrels, fixed mandrels and ball mandrels. Pressure dies, clamp dies and mandrels may also be made of different materials depending upon the tube material.

Mandrels and wiper dies are consumable items requiring one to keep track of their usage and manage their timely replacements.

Together these variables add additional parameters that increase the number of tube bending tool components to be stored, maintained and managed.

In addition to the main components of the bending tool set mentioned above, there are spacers, tube guides, interface plates etc. Tube bending department bend many different components made of different materials and dimensions and hence the number of tooling parts required in their repository quickly reaches a substantial number.

Bending tool set dimensions also change based on machine size and the size of the machine depends on several parameters.

Take a look if you want to know how to choose the right tool bending machine for your production

What is Tool Room?

Recognizing this difficulty, BLM GROUP has developed the Tool Room, a software package to help the user to manage and use his tool library.

The Tool Room:

- catalogs all the tube bending tool components of various tool sets and prepares a database;

- appropriately combines components to produce the required tube bending tool set;

- verifies which components are present in the database;

- checks whether they are available, or they are being used/planned to be used on a machine;

- if a given component is being used or not present on the database, allows the user to easily select another combination of tube bending tool components (for example a pressure die with a different length);

- keeps track of tube bending tool usage and allows the user to set usage levels to signal imminent end of life and manage their future replacement.

Tool Room has three separate modules:

Tool Room integrated with VGP3D

This module collects information about component requirements based on the part to be made and resides within the tube bending programming software VGP3D on the machine and on the design office PC depending upon the number of licenses.

Tool Room Production

This module allows the user to assemble the tool set, save it then schedule it to the planned production.

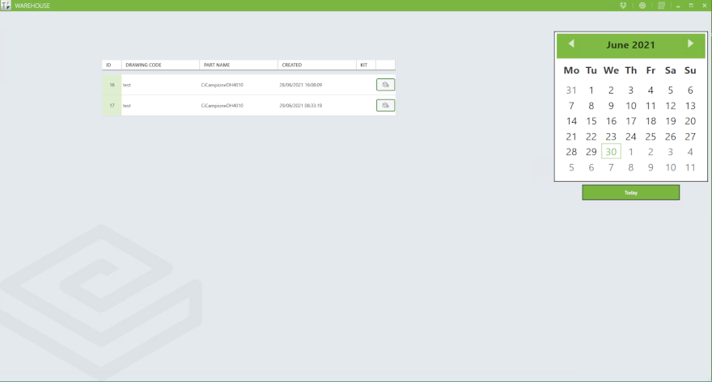

Tool Room Warehouse

This module manages the logistics of the tool set –supplying it to the production department, returning it to the warehouse etc.

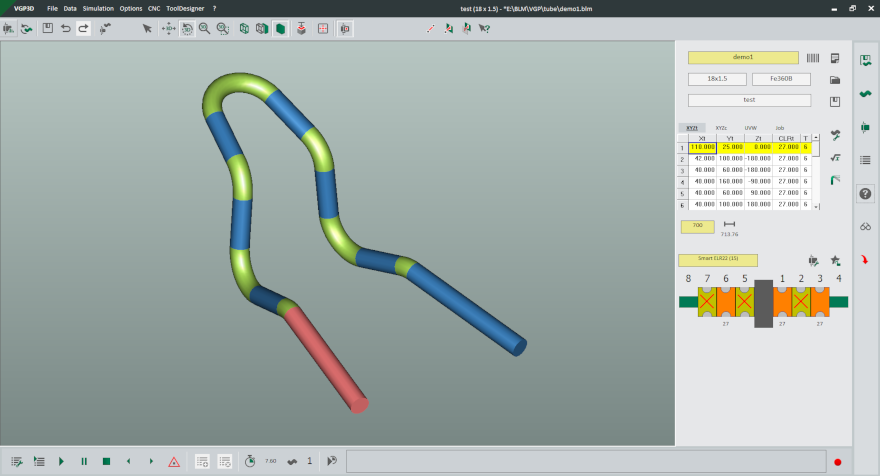

Tool Room integrated in VGP3D collects the tube bending component requirements, based on the part to be done.

Tool Room integrated in VGP3D collects the tube bending component requirements, based on the part to be done.

How does Tool Room work in practice?

Step 1 – Programming the part and knowing the right tooling

When the user programs a new part using VGP3D or opens a program for a part that was already manufactured in the past, VGP3D knows all the tooling components necessary to put together the required tube bending tool set because of the Tool Room module integrated within VGP3D.

Bent tube programmed on VGP3D.

Bent tube programmed on VGP3D.

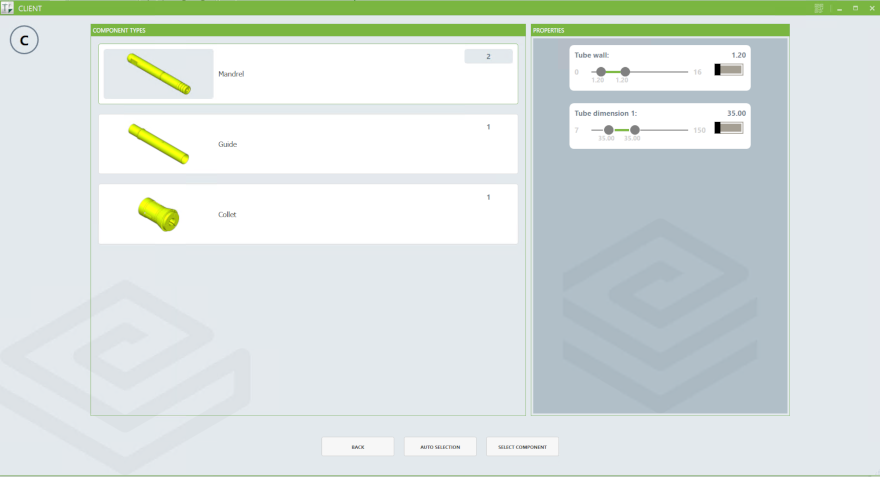

Step 2 – Looking for alternative tube bending tool components when the first selection is not available

The Tool Room module integrated within VGP3D compares the requirements with the tube bending tool component database and presents the user with the results.

- If all the components are present and available, the user knows that the required tool set can be assembled;

- If a component is present in the database but not available, the Tool Room allows the programmer/designer to widen the search to look for an alternative component in the database (for example, a pressure die with a different length);

- If the tool set was already put together in the past and was used on the machine, Tool Room would keep track of the requirements and propose the same tool set. In this way, all tool setting parameters successfully used in the past, can be readily applied and used for current and future production.

Tool Room allows the programmer/designer to widen the search to look for an alternative component in the database (for example, a pressure die with a different length).

Tool Room allows the programmer/designer to widen the search to look for an alternative component in the database (for example, a pressure die with a different length).

Step 3 – Download the technical drawing of the tube bending tool components with Tool Designer

All the mechanical details and usage data of a given component is readily displayed to help the programmer/operator to identify the component and make the right decision.

If one of the components of the tool set is not present on the database, the designer can download the drawings for that part using the Tool Designer service offered by BLM GROUP.

At this point, the designer/programmer has found the appropriate tool set to bend the tube and has checked the components’ availability. The next step involves Tool Room Production.

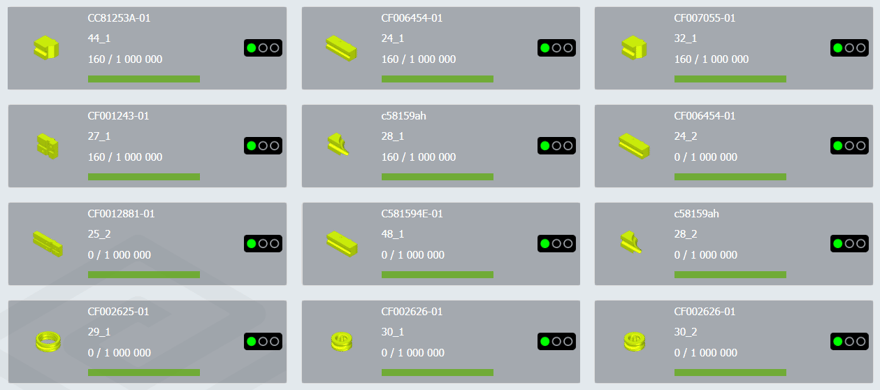

With Tool Room the user identifies the appropriate tool set to bend the tube and checks the components’ availability.

With Tool Room the user identifies the appropriate tool set to bend the tube and checks the components’ availability.

Step 4 – Schedule the tooling usage

The production manager opens the saved VGP3D program and retrieves the information about the components required to assemble the tool set and generates a “Production Request” which contains all the details of the tool set. The production manager then selects the individual components and virtually assembles the tool set with scheduling; adding the specific date the tool set will be used on the machine. If multiple machines are suitable for bending the part, a specific machine can be assigned.

The production manager selects the individual components and virtually assembles the tool set with scheduling; adding the specific date the tool set will be used on the machine.

The production manager selects the individual components and virtually assembles the tool set with scheduling; adding the specific date the tool set will be used on the machine.

Step 5 – Easily manage tube bending tool logistics

Tool Room Production manages the information about tools stored in different locations – for example if a user has multiple factories in different locations, each one with its own collection of tube bending tools.

At this point the Tool Room Warehouse module comes into play. The information for the tool set put together by Tool Room Production is made available to the Tool Room Warehouse module on the scheduled date. After the tool set is issued for use on a machine, the Tool Room considers the components making that tool set to be temporarily not available. Once the tool set is actually mounted on the machine and is being used, it is shown as “IN USE”, until then it is shown as “IN TRANSIT”.

The outward and inward movement of parts from and to the repository can be simplified by using a bar code scanner and by marking the components with the appropriate bar codes, QR codes or Data matrix.

Parts can be marked with a QR code, bar code or data matrix to simplify their logistics.

Parts can be marked with a QR code, bar code or data matrix to simplify their logistics.

Step 6 – Check tube bending tool usage and lifetime

The Tool Room collects information about the tube bending tool usage from the machines (i.e. number of bends carried out using the tooling) and updates this information in the database when the tool set is returned post production. If a machine does not have the Tool Room installed on it, the information about the tool usage can be manually entered.

Conclusion

This is a preliminary introduction to the latest addition to the BLM GROUP’s software suit – Tool Room. BLM GROUP developed it to address the real-life difficulties faced by tube fabricators in managing the large number of tube bending tools to be used on many different tube bending machines.

As with all the software products developed by BLM GROUP, it will continually be developed further by incorporating new ideas and concepts based on user feedback.