Through innovation, entrepreneurs can achieve many advantages for their company, their people and their customers. In this article, we will discuss some aspects which may be particularly interesting and that may help or inspire anyone who wants to make innovation the focus for their future growth and sustainability.

Introduction, growth, maturity and decline of a product

We live in a world where nothing lasts forever and where the products and services we design, make and sell change quickly.

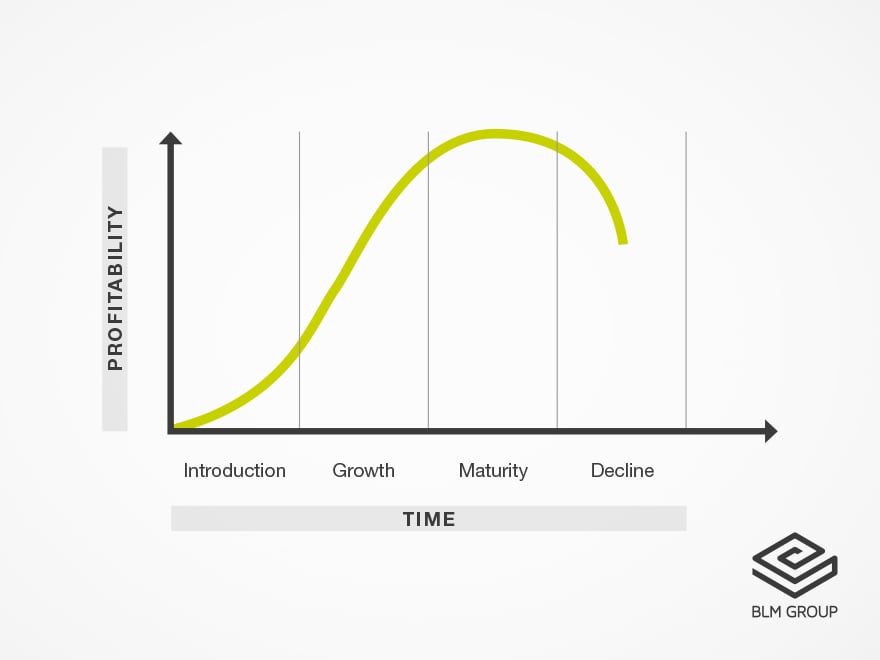

From introduction into the market to obsolescence, this time – known as the product life cycle – is crucial for the strategic choices of a company.

The product life cycle can be divided into four main phases: introduction, growth, maturity and decline.

The product life cycle can be divided into four main phases: introduction, growth, maturity and decline.

The product life cycle has four main stages:

- introduction: The product is launched into the market;

- growth: The product starts to be sold and used by people;

- maturity: The product continues to be sold, but at the same time the market is becoming saturated;

- decline: The product becomes old. It starts to be sold at a lower and lower price until it becomes obsolete.

Given the physiological decline of all products, a company constantly needs new products to generate revenue and added value. Innovation is the fundamental way to do so.

Innovation can be used to step out of the decline stage where survival is played out simply by the lowering of the price of the product and consequently reducing the profit margin, to start a new life cycle or revamp a product.

If innovation is your mission, read this article

Guarantee the strength of your company through valuable investments

For a company, innovation does not only mean designing new products. It also means acquiring new technological tools that can be an added value in the various stages of a product life cycle.

Manufacturers will subsequently be able to improve the characteristics of their product, which will acquire more value than similar products made by competitors. The products can be used in areas in which specifications are more stringent and therefore they can be sold at a higher price.

Take the construction of chassis for large industrial vehicles, for instance. Many manufacturers used to cut and prepare tubes and profiles to be assembled with hand tools, such as plasma torches, grinders and drills, putting them in a jig and then welding them together manually. The absence of precise references on the tube, the inaccuracy of the jig and the total reliance on the operator's experience could cause considerable errors on the final geometry of the structure.

With the introduction of advanced laser cutting machines capable of processing automatically tubes and profiles with exact fit-up, and also equipped with user-friendly software, it’s possible for manufacturers to cut pieces with extreme precision and improved accuracy. The quality and precision of the final structure is significantly better and becomes easier and faster to produce.

For large commercial vehicle chassis manufacturers, this translates into increased profit margin. In other words, high-value investments in machinery and technology capable of surpassing the market competition are needed to ensure the stability of a company.

Innovation and economic profit

A company combines manpower, machinery, work areas, raw materials and finished products to generate profit. A company's accounting profit is nothing more than the difference between the turnover deriving from the sale of its products (or services) and production costs.

Accounting profit is a tangible element that companies are directly accountable for, but it is not the only benchmark used to determine a company's performance, nor is it the most important indicator on which to base future business decisions, as it does not take opportunity costs into account.

Opportunity cost is the loss of potential gain from other alternatives when one alternative is chosen.

For a company, innovation is certainly a cost, for instance when buying a new machine. However, if the company decides not to innovate, the cost becomes that of a missed opportunity.

An example of this could be an industrial vehicle manufacturer who decides to insource the products of chassis by purchasing highly innovative tube and profile processing systems. As a result of this choice, the manufacturer will be able to source high-quality components at a much lower price than if they were bought from a supplier. Furthermore, the systems can also be used to develop prototypes for the R&D department or for use in other productions. The economic disadvantages that would result from not taking this decision would result in an opportunity cost that would weigh on its economic profit.

The characteristics of an innovative technology

How can you understand if a technology can be a game changer for your business?

One of the most important aspects of innovation used to be the ability to provide your company with sufficient energy to produce more or exceed the limits determined by human strength. Then it was the turn of mass production, and in those days, innovating meant acquiring systems capable of producing large volumes of parts or products very fast.

Today, one of the fundamental aspects of innovation is the acquisition of smart machines with machine-to-machine communication, access to real-time data, and integration to your company’s ERP. Smart machines can help businesses control and understand every aspect of their operation, including the behavior of the material they are processing and leverage data to boost productivity, improve processes, and drive growth.

From this perspective, here are some characteristics that a company looking for new production equipment should look for:

- Flexibility: Many manufacturers today have to deal with smaller batches, sometimes with only a few parts or prototypes. Production flexibility, i.e. the ability to move from one production to the next as quickly as possible, is crucial.

- Ease of use: It is increasingly difficult to find specialized operators, so the machine must be equipped with the experience. The interfaces and programming software of a system should be simple to use and allow operators and programmers to produce complex parts and machining operations quickly and efficiently.

- Sustainability: Today, systems with low environmental impact, in terms of energy consumption, waste, and low maintenance, are preferred.

- Reliability: Plant technology is becoming more and more advanced and this requires not only being reliable, but also in case of failure or breakage the manufacturer can guarantee a timely service supported by modern tools, such as augmented reality or remote assistance.

- Interconnectivity: Today's plants must be able to communicate with each other and exchange data with ERP systems.

Embracing technology Industry 4.0

Talking about innovation in production today leads the discussion down the path of Industry 4.0, a trend of integration of production technologies with the most advanced digital technologies available on the market today. This is direction that the world industry is taking to respond to some major needs:

- reduction of production batch sizes;

- products characterized by increasing quality and complexity;

- need to make production processes more efficient.

All this pass through the integration of the production plants horizontally and vertically through the MES (Manufacturing Execution System) with the ERP (Enterprise Resource Planning) system of the company to allow the smart factories to respond to external or internal needs quickly.

Talking about innovation in production today leads to Industry 4.0.

Talking about innovation in production today leads to Industry 4.0.

To achieve this, Industry 4.0 addresses many technological areas including: advanced manufacturing solutions, augmented reality, big data, industrial internet, IT security, etc.

One of the most interesting aspects of the technologies that characterize Industry 4.0 is their scalability, that is the possibility to be implemented step by step, allowing companies to build their own smart factory by purchasing machinery that enables this technology and modulated investments.

New equipment purchases may reduce taxes on business profits

Depending on the country your business is located, you may be able to take advantage of government programs or tax incentives to help with the equipment purchase. Check your local government websites for available programs and resources.

In the United States, there are two big tax savings for small to mid-sized manufacturers.

100% Bonus Depreciation

- Applies to any dollar amount of qualified capital expenditures

- Available for both new and used equipment

- Typically taken after section 179 spending cap is reached

Section 179 Deduction

- Allows small to medium-sized manufacturing companies to deduct the first $1,040,000 of equipment purchased from their taxable income.

- For equipment purchases up to $2,590,000, this deduction is available in full.

- Deduction phases out dollar-for-dollar from $2,590,000 to $3,630,000 and is not available for purchases over $3,630,000

There is also the R & D Tax Credit given to businesses large and small that design, test, and implement new ways of conducting business; the same driving factors of Industry 4.0.

To determine which incentives your business may qualify for, it’s always best to consult your tax professional.