When dealing with laser-cutting square tubes and sorted packages it is certainly possible to pre-orient the tubes in the Lasertube system loader to ensure the correct angle is maintained when the tube is transferred to the working line. The laser-cutting of round tubes from generally unsorted packages is a different matter. There is no way to reliably constrain the loading angle of each tube so that the weld seam is where you want it to be. Maybe even more importantly, you cannot make the angle the same for all tubes.

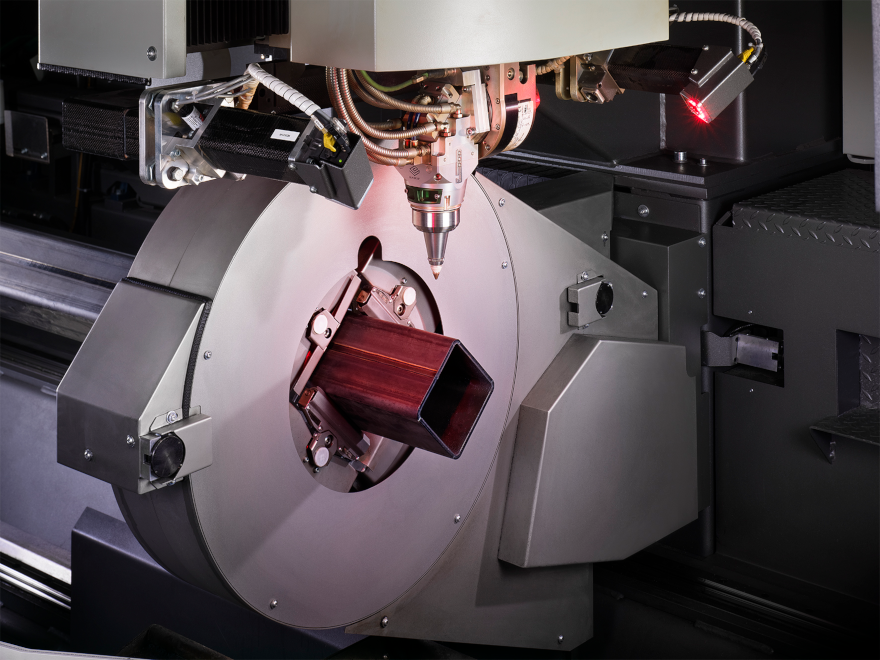

To make the process reliable without generating waste, the solution is to detect the weld on the tube to be lase cut after it has been loaded. The BLM GROUP Lasertube systems can do this by using an optical device installed in the cutting enclosure called Active Weld.

If you would like to learn about the innovative welding technologies that are revolutionizing the market beyond handling tube welding seams, you may find the robotic laser welding cell from BLM GROUP interesting.

When dealing with laser cutting of square tubes and sorted packages you can opt to pre-orient the tubes in the Lasertube system loader.

When dealing with laser cutting of square tubes and sorted packages you can opt to pre-orient the tubes in the Lasertube system loader.

How the tube weld seam detection system works: Active Weld

The loaded tube is illuminated to highlight the weld seam – either inside or outside the tube – allowing a camera to automatically detects its position. The information is sent to the CNC that compares the detected data with the information contained in the part program (or set by the operator on the console).

The machine then turns the tube so that the job starts at the angle set during programming. The same angle will be replicated for all the tubes in the bundle. This is the only way to ensure the parts looks the same with each having the weld seam facing the same direction.

The tube is illuminated at the end of the loading operation to highlight the weld seam.

The tube is illuminated at the end of the loading operation to highlight the weld seam.

The operator can activate an initial training procedure if the weld mark is particularly slight, or the tube has multiple marks that could mislead the automatic detection system.

The image framed by the Active Weld camera can be seen on the console monitor to define the weld area on the first tube of the bundle, specifically its width, contrast level and assigned confidence level in order to eliminate any uncertainty.

The system will search for the same pattern on all the other tubes without requiring further operator intervention for as long as the detected confidence level is above the threshold. The machine will ask the operator to visually reconfirm the weld seam if the recognition system detects a confidence level below the set minimum threshold.

This interactive mode prevents the machine from producing parts with an incorrect orientation.

Discover the BLM GROUP solutions for optimising nesting for tube laser cutting

When you need to detect weld seams for tube processing?

Now that you know that the solution exists and that it is reliable, let us take a look, in sequence, at the most frequent cases in which the weld seam needs to be identified.

All parts are the same

To guaranty the repeatability of produced parts all tubes must be worked with the:

- weld seam in the same position;

- same face in the same initial position in the case of square or rectangular tubes;

- same initial angle in the case of round tubes (e.g. weld seam always at 90° to the first cut).

Thick weld seam

The laser technological parameters, automatically selected by the machine to be optimal on the nominal thickness of the tube, may not be effective when cutting across the weld seam.

Consequently, the scrap may not detach, or the piece may not separate at the end of the job causing an interruption of the automatic cycle and the need to intervene and manually detach it from the rest of the tube.

Tube with pronounced weld seam thickness laser cut on a Lasertube system.

Tube with pronounced weld seam thickness laser cut on a Lasertube system.

To solve these problems – especially the second one – the operator can choose to manually set a higher laser power which then must be used for the entire job because the position of the weld seam is unknown. As a result, more heat will be transferred to the workpiece and the risk of burns will be greater.

Instead, knowing the position of the weld allows the machine to modify the laser parameters only at the thickest pass, keeping the standard parameters for the rest of the cut and obtaining the best possible laser cutting quality. The part will always detach and the process will be carried out reliably and without interruption.

Appearance needs

When you want to hide the weld because the tubes will remain in sight without being painted you can choose to orient it so that the weld remains on the concealed side.

Mechanical robustness

The weld area has been thermally altered, i.e. it has a different mechanical resistance than the rest of the tube due to the effects of the heat transmitted during the sealing phase (tempering). This difference results in an asymmetry in the mechanical behaviour of the tube which can alter the result of the job.

How to detect the weld seam in a tube bending machine

Also for tube bending, is preferred if not essential to manage the weld seam position. Once again, appearance needs may require the tube to be properly oriented before starting the bending operation, as is often the case in the furniture industry.

First of all, it is advisable to avoid placing the weld seam on the extrados (i.e. the outer side of the bend) because this is the part of the tube that is stretched as a result of the deformation. The weld seam changes the mechanical properties of the metal – hardening it – due to the heat transferred and this can lead to cracks. Furthermore, the mechanical strength of the welded tube is no longer uniform and symmetrical.

When bending the tube, the weld seam should not be placed on the extrados.

When bending the tube, the weld seam should not be placed on the extrados.

Allowing the weld to position itself randomly would result in different springback effects according to how the tube is loaded (if it is not repositioned) leading to a lower repeatability of the tube bending process. Ultimately, the weld seam must be detected and positioned systematically and consistently.

The procedure is similar to the one already described for Lasertube systems to try to ensure that the weld has the desired orientation (particularly for round tubes). An error is always a possibility, which is why it is preferable to use a sensor positioned close to the bending head.

The optical weld detection sensor is activated before starting the tube bending cycle and detects the position of the color change on the tube rotating underneath, specifically dark weld on light-coloured tube, typical of stainless steel or light weld on dark profiles more frequent in mild steel tubes.

Once the weld has been detected, the tube bending machine will rotate the tube to the correct initial orientation.

This approach works when the weld seam is visible on the outside of the tube. If the weld seam is only visible on the inside, the operator can simply mark the tube on the outside by tracing a line. This is a workaround but one that solves both the technical and appearance requirements without unduly burdening the productivity of the machine.

The optical weld detection sensor is activated before starting the tube bending cycle.

The optical weld detection sensor is activated before starting the tube bending cycle.

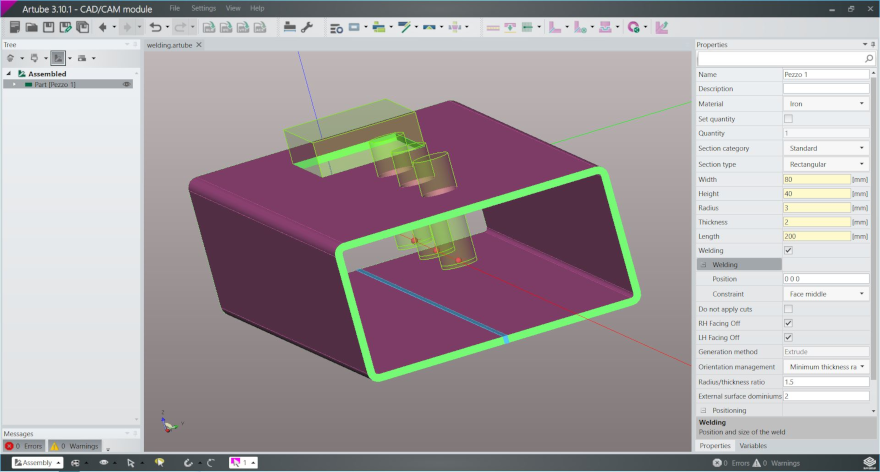

How to define the position of the weld seam when creating the part program

Position assignment is easy using the graphic 3D CAD/CAM available for both Lasertubes and BLM GROUP tube benders, ArTube and VGP3D.

Clear and unambiguous graphic help is provided for dealing with weld seams just like all the other jobs on the tube, such as the cutting of geometries and the planning of bends. The complete workpiece with the required orientation will be visible in preview with the weld in the required position.

Position assignment is easy using the graphic 3D CAD/CAM available for both Lasertube systems and BLM GROUP tube benders.

Position assignment is easy using the graphic 3D CAD/CAM available for both Lasertube systems and BLM GROUP tube benders.

The machine will receive the information, activate the detection device at the start of each new tube and set the orientation required during part design within seconds.

All this means no possible operator error, no rejects or different parts and reliable processing on all parts in the batch.

You can also set the weld seam position on the machine using the graphic interface in a few simple guided steps.

Conclusions

The weld seam search is one of the many features available on BLM GROUP systems. It is the result of thousands of installations and decades of optimization in all sectors and with all types of tubes. This experience in tube processing translates into reliability and productivity, the two main items of interest for any customer who wants to maintain competitiveness.