The Belgian based metal construction company Walcarius NV wanted to stand out in the steel construction world by exploiting tube and beam machining and their interlocking potential offered by 3D laser cutting.

The company has been using the LT24 - BLM GROUP's largest Lasertube system, for several years to supply high-precision 3D laser-cut beams and section bars for assembling structures without welding. “Our dream is to create a kind of building package for the steel construction market” declared Philippe and Francis Walcarius, managers of the family-owned business.

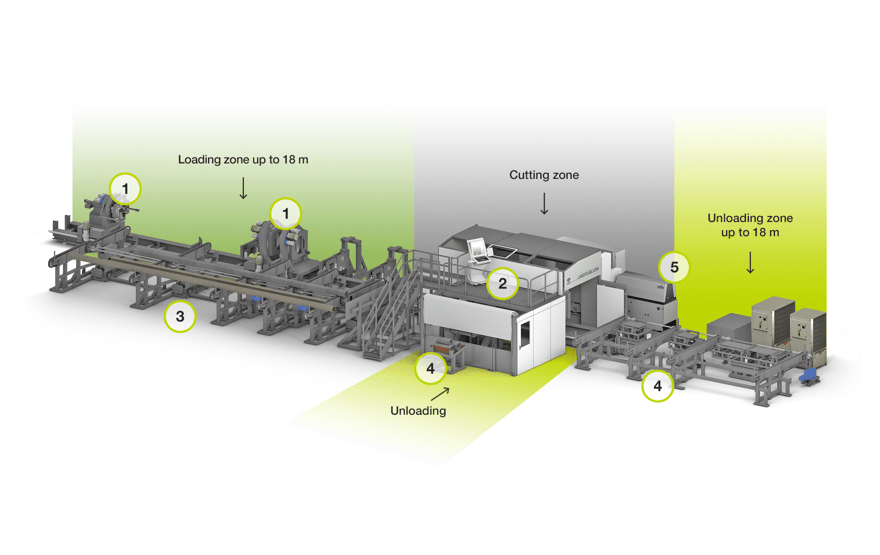

LT24 Lasertube system for large tubes and sections from BLM GROUP. The numbered parts are the main parts of the machine: 1) Spindles; 2) 3D laser cutting area; 3) Loader; 4) Unloader; 5) Laser source.

LT24 Lasertube system for large tubes and sections from BLM GROUP. The numbered parts are the main parts of the machine: 1) Spindles; 2) 3D laser cutting area; 3) Loader; 4) Unloader; 5) Laser source.

From laser cutting of sheet to laser cutting of tubes

Strategic investments in large sheet processing machines to meet market demands have always been a fundamental contribution to a company's growth.

The huge boost that 2D laser cutting determined in the processing of large-size sheets with its speed and precision inspired brothers Philippe and Francis Walcarius to consider the possibility of using lasers systems to work large tubes and beams as well.

This droves them to invest in a Lasertube LT24 made by the BLM GROUP which has specialized for many years as a manufacturer of laser cutting systems for the construction industry.

“The ability to laser-cut complex holes and contours on tubes up to a maximum diameter of 610 mm, and on IPE500 / HEA400 / HEB300 hollow section bars and beams up to 500 mm x 300 mm, set us apart in the market right away. There were not many machines of this size in our specific sector until mid-2018.”

Francis Walcarius

Innovative production for steel construction

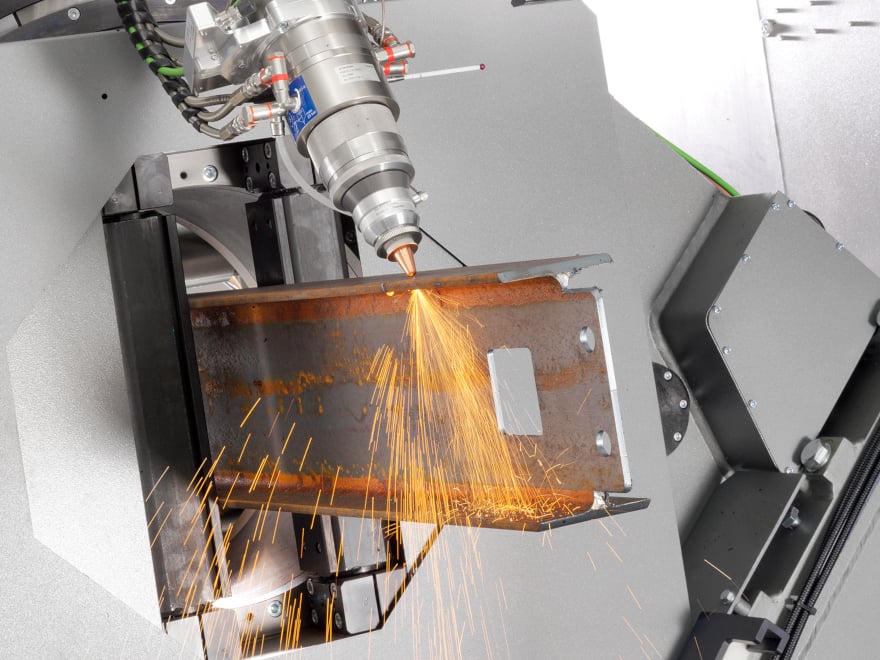

Drills and saws are still primarily employed in steel construction to make holes and cut tubes, beams and section bars; the use of 3D laser systems are an exception. Conventionally, these jobs are limited on the hole size and the maximum sectioning angle of 45°.

Additionally, conventional tools cannot be used to create contours and slotted holes and the tools must be changed for each hole size. The creation of slotted holes and contours requires additional processing steps using different technologies, such as plasma cutting and/or milling, which means more time and lower quality.

Contour cutting with plasma is much less accurate than laser cutting and cannot be integrated into the drilling/sawing process.

Find out the other differences between laser and plasma cutting

Laser technology overcomes many of these limitations and makes it possible to cut holes and contours at high speed with reproducible precision in a single process.

“While making a hole with a drill takes several minutes, including changing the tool to the right diameter, the laser makes any hole in seconds” the manager pointed out. “There is only one tool for all holes and geometries, with the advantage of shorter production times. Multiple operations on a single system also eliminate the need to move and reposition large, heavy parts on the shop floor.”

While making a hole with a drill takes several minutes, including changing the tool to the right diameter, the laser system makes any hole in just seconds.

While making a hole with a drill takes several minutes, including changing the tool to the right diameter, the laser system makes any hole in just seconds.

Pioneers of smart joints with 3D laser processing of beams and tubes

The potential of 3D laser cutting for the assembly of structures for the steel construction industry appeared especially promising for brothers Philippe and Francis Walcarius.

Where beams were previously connected using fastening tabs that had to be welded to a column, now male-female connections are made, where beams and tubes fit together without welding, with an accuracy that depends on laser processing and not on human skills on-site.

This offers completely new connection possibilities for steel constructions, to the extent that we are developing all kinds of structures ourselves, such as carport construction kits that customers can assemble themselves without welding and that are also lighter.

Laser cutting can also be used to produce highly articulated structures for public buildings, such as complex roofs, bridges, skylights, etc., which can be perfectly adapted and quickly assembled. We will have to demonstrate these technologies to architects, in particular.

Carport for electric vehicles with integrated solar panel.

Carport for electric vehicles with integrated solar panel.

Further advantages of laser cutting in the steel construction sector

“We showed our customers the possibilities of joining tubes and beams and this created a demand for steel structure parts made by 3D laser cutting. We attended construction trade fairs, among other events, to show more companies that 3D laser-cut structures can be built faster and are lighter. Although the real revolution has not yet started, we have seen that, from a design standpoint, it is mainly the younger generation of engineers who have grasped the opportunities of this building method” observed Francis Walcarius. “As a supplier, if you are involved in the design phase, you can still participate in the production and show what is possible with 3D laser cutting, saving on welding preparation.”

Interlocking between pipe and IPE achieved through the precision of 3D laser cutting.

Interlocking between pipe and IPE achieved through the precision of 3D laser cutting.

Transferring cost savings to the customer

By investing in 2D and 3D laser cutting systems, the metal construction company can produce faster, shorten lead times and save costs, offering numerous advantages to the customer.

“Customers compare lead times, assembly times and sustainability, as well as prices.”

“Other industries working with smaller tubes, up to 200 mm in diameter, have already acknowledged the advantages of construction and now rely on different suppliers for laser cutting work. For instance, OEMs from the food industry are turning to us for laser tube cutting of tubular frames.”

Expanding your business with laser cutting

The investment in the LT24 from BLM GROUP has brought more work to Walcarius, especially from new customers.

“The high productivity means with we can process more steel per day and the number of orders has increased to up to 2,500 per year. We process 5,000 tonnes of sheet metal, tubes and sections per year. For now, we still manage to get the work done in one shift, but soon we should add one more shift” said the manager.